Mass Spectrometry & Gas Analysis

The control of the vacuum as well as the control of gas flows is a core element of mass spectrometry and gas analysis. Precise shut-off and control, o...

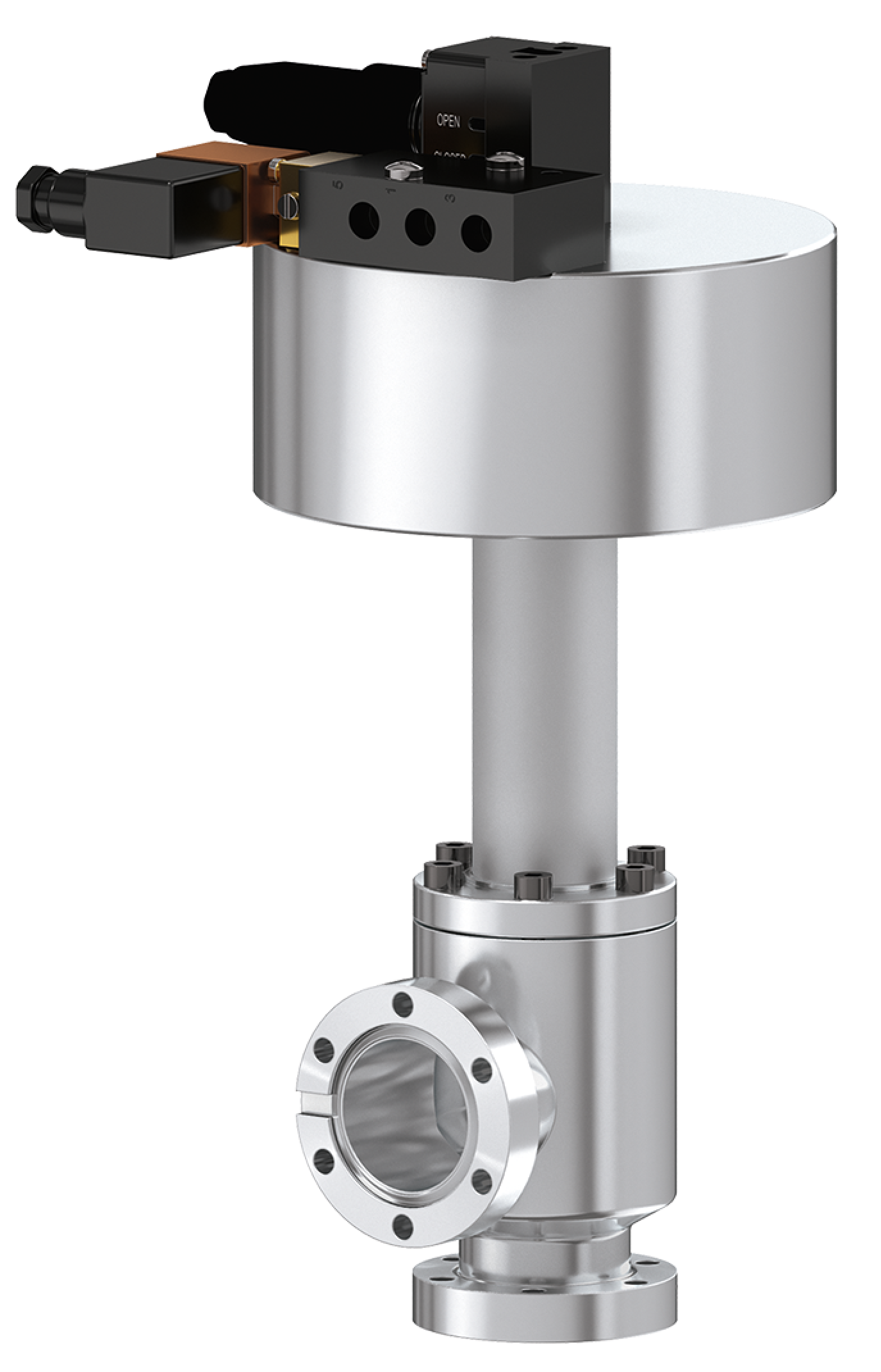

Read moreThe 57.1 XHV All-Metal Angle Valves are laid out for reliable isolation for UHV and XHV applications, high and low temperature environments as well as radiation up to 108 Gy.

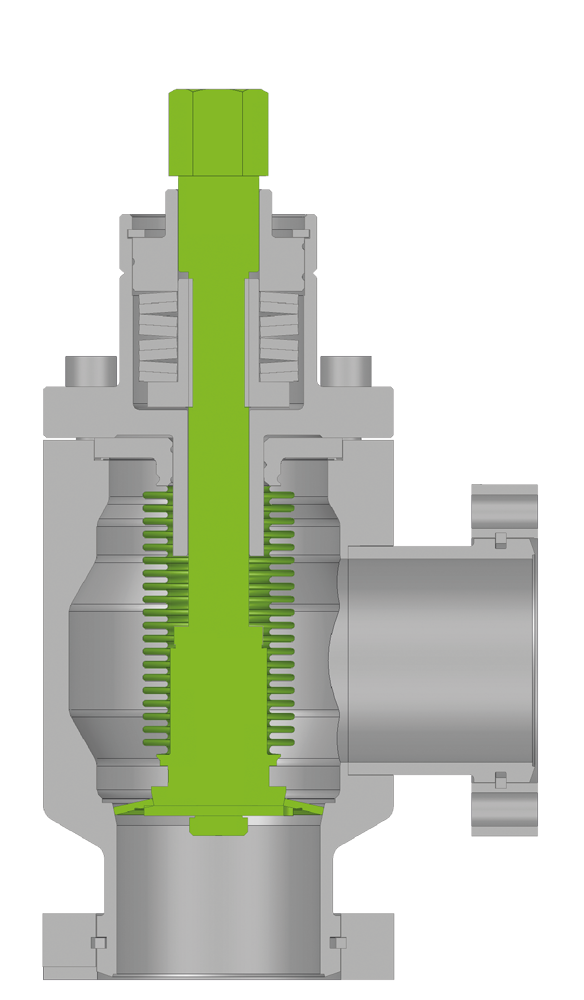

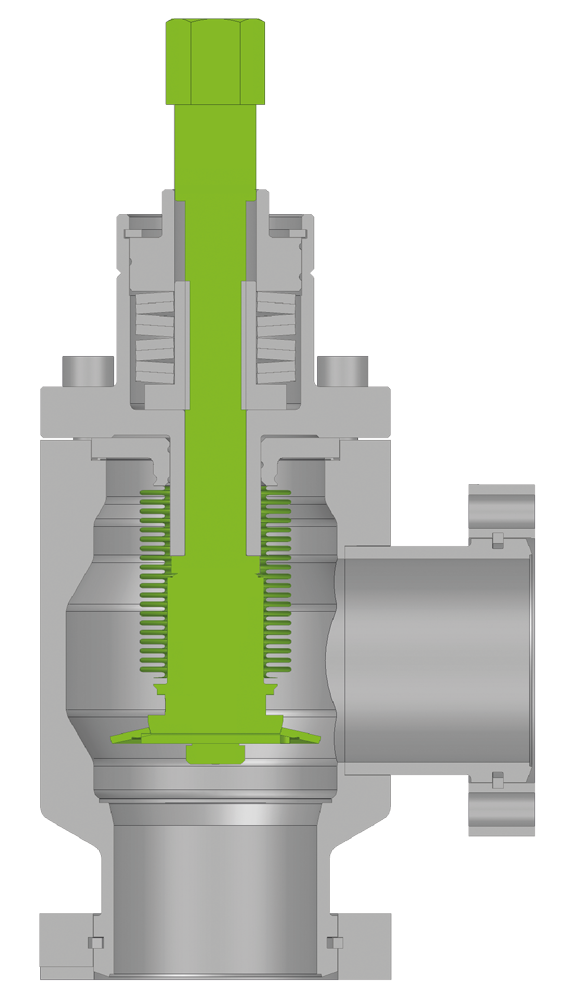

These all-metal angle valves are designed for maximum conductance and they are equipped with VATRING “hard on hard” sealing technology. This dynamic all-metal sealing system is characterized by consistent reliable sealing and constant closing forces. It enables high sealing forces with comparable low axial forces. The sealing partners are made from stainless steel and they deform elastically only.

The valves may be baked to 450 °C in open or 350 °C in closed position. They are designed and tested for a lifetime of 10 000 cycles.

Already installed in thousands of demanding applications under various process conditions, the 57.1 series have proven their outstanding reliability.

Various design options in actuation, flange connections or additional vacuum ports make it easy to integrate the valves into any vacuum application.

A key feature is the VATRING sealing system, also used in other well-known VAT all-metal gate valves. Due to the constant sealing force these valves are built not only with manual actuators, but also with pneumatic double acting and pneumatic spring closing actuators. They are the only all-metal angle valves in the world which are pneumatic actuated!

The valves are available in sizes DN 10, 40, 63 mm (57.1).

Standard flange is CF-R, from CF-R 16 to CF-R 63 with the rotatable flanges being fixed in place. Various other options are available.

| Sizes | DN 10 (⅜"), DN 16 (⅝"), DN 40 (1½") | |||

|---|---|---|---|---|

| Actuator | Manual | Hexagon Head | ||

| Pneumatic | Single acting with closing spring (NC) or Double acting | |||

| Body Material | Stainless Steel | |||

| Feedthrough | Bellows | |||

| Standard Flanges | CF-R | |||

| Leak Rate | Valve Body | < 1 × 10-10 mbar ls-1 | ||

| Valve Seat | < 1 × 10-10 mbar ls-1 | |||

| Pressure Range | XHV to 5 bar (abs) | |||

| Differential Pressure | On the Gate | ≤ 5 bar | ||

| At Opening | ≤ 1 bar | |||

| Cycles until first Service | 10 000 | |||

| Bake-Out Temperature | Valve Body | ≤ 450 °C open / ≤ 350 °C closed | ||

| Manual Actuator | DN 16 – 40 | ≤ 450 °C open / ≤ 350 °C closed | ||

| Pneumatic Actuator | ≤ 150 °C (single acting with closing spring) ≤ 200 °C (double acting) |

|||

| Solenoid Valve | ≤ 80 °C | |||

| Position Indicator | ≤ 80 °C (Option: 200 °C) | |||

| Heating and Cooling Rate | ≤ 60 °C h-1 | |||

| Material | Valve Body | AISI 316L (1.4404, 1.4435) | ||

| Mechanism | AISI 316L (1.4404, 1.4435) | |||

| Bellows | AISI 316L (1.4435) | |||

| Seal | Bonnet, Gate | Metal (silver plated) | ||

| Mounting Position | Any | |||

| Solenoid Valve | 24 VDC, 2.5 W (others on request) | |||

| Position Indicator: Contact Rating | Voltage | ≤ 50 VAC/DC | ||

| Current | 80 °C: ≤ 1.2 A | 200 °C: ≤ 1.0 A | ||

| Valve Position Indication | Visual (Mechanical) | |||

4.5 billion years – this is the unimaginably large number that researchers today estimate to be the age of our Earth. In comparison, the age of geochr...

The Rare Isotope Science Project (RISP) was originally established in 2012 as a master plan to build a heavy-ion accelerator (RAON) in Korea. Completi...