Let’s Go for Muons!

In 1936, when studying cosmic radiation, the physicists Carl D. Anderson and Seth Neddermeyer discovered a previously unknown elementary particle: the...

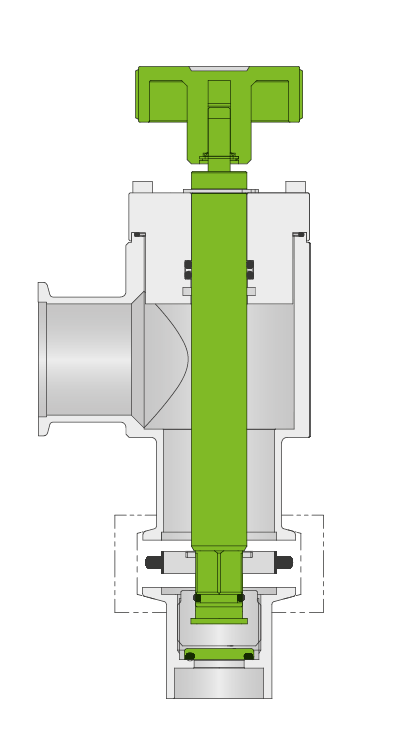

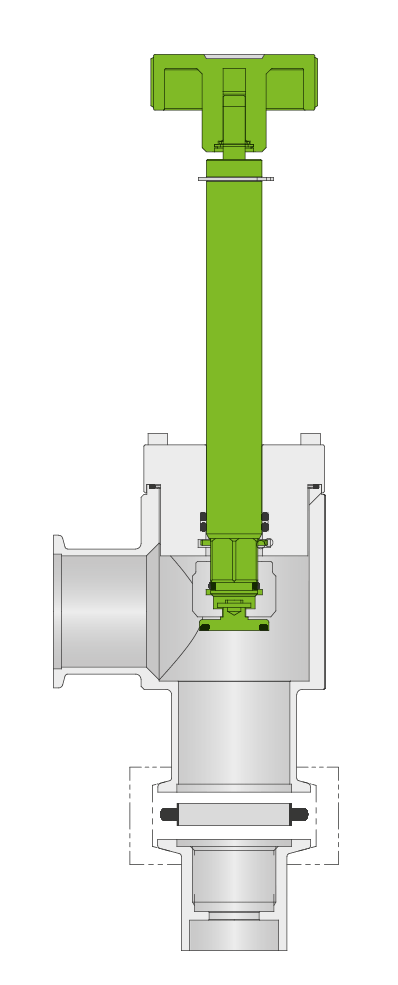

The 23.0 Valve Mechanism and Pump-Out System consists of two elements: the pump-out port and the mechanism to open the port in a controlled and protected manner.

Since pump-out ports are normally used only during maintenance procedures to pressure compensate vacuum vessels or systems, the 23.0 Pump-Out Port has a stainless steel design and an FKM seal to guarantee a long lifetime and full functionality even after long periods without use.

The pump-off port is designed to prevent unintentional openings by only allowing it to be opened with the matching 23.0 Valve Mechanism which works like a key. Only when it is correctly connected to the port can the port be opened. The valve mechanism can be connected to a purge gas system, for example to ensure that the vacuum vessels or systems only come into contact with the permitted media.

The 23.0 Valve Mechanism is made of lightweight aluminum for easier handling. The port is opened by means of a handwheel, which is self-locking and built into the shaft head of the pump-off port. The 23.0 Valve Mechanism can be used for multiple 23.0 Pump-Out Ports.

Installed in thousands of demanding applications under various process conditions, the 23.0 Valve Mechanism and Pump-Out System has proven its outstanding reliability.

The 23.0 Valve Mechanism and Pump-Out System is laid out for a pressure range of 1 ₓ 10-8 mbar to 2.5 bar (abs).

It is available from DN 16 – 40mm (5/8“ – 1½”). The standard flange is ISO-KF. To connect the valve mechanism to the port a centering ring with O-ring and a clamping ring are required. These have to be ordered separately, if required.

Features:

Benefits:

| Valve Mechanism | Pump-Out Port | ||

|---|---|---|---|

| Sizes | DN 16 (⅝"), DN 25 (1"), DN 40 (1½") | ||

| Actuator | With Self-Locking Handwheel | ||

| Body Material | Aluminum | Stainless Steel | |

| Feedthrough | Shaft | Shaft | |

| Standard Flanges | ISO-KF | ISO-KF | |

| Leak Rate | 1 × 10-8 mbar ls-1 | 1 × 10-9 mbar ls-1 | |

| Pressure Range | 1 × 10-8 mbar to 1 bar (abs) | 1 × 10-8 mbar to 1 bar (abs) | |

| Temperature | Valve Body Handwheel |

≤ 150°C ≤ 50°C |

– – |

| Material | Body Shaft Plate |

EN AW-6060 (3.3206) AISI 304 (1.4301) – |

AISI 304 (1.4301) – AISI 304 (1.4301) |

| Seal | Bonnet, Feedthrough, Plate | FKM (Viton®) | FKM (Viton®) |

| Mounting Position | Any | Any | |