Proton Therapy

Proton therapy as a medical treatment process is implemented in different technical concepts, with different requirements for the vacuum systems invol...

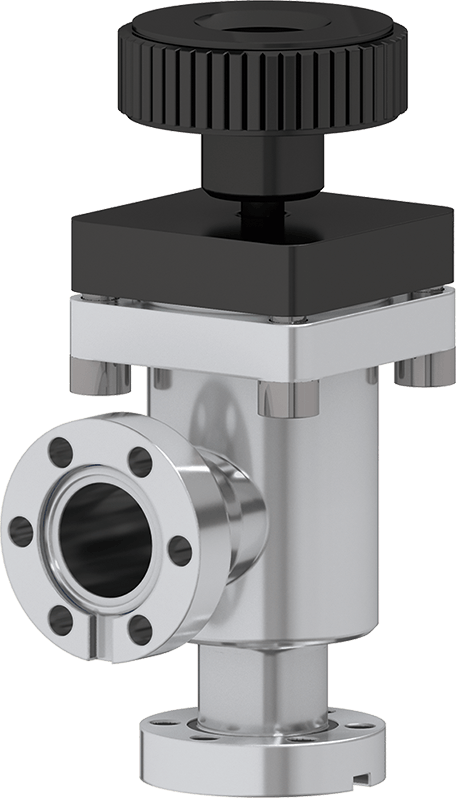

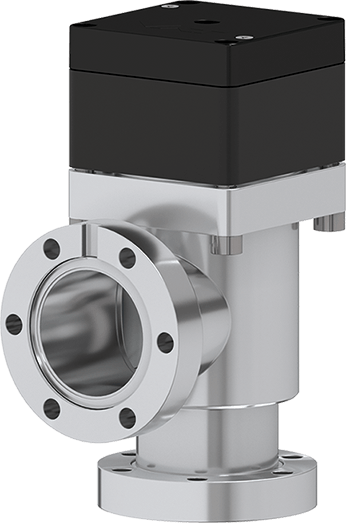

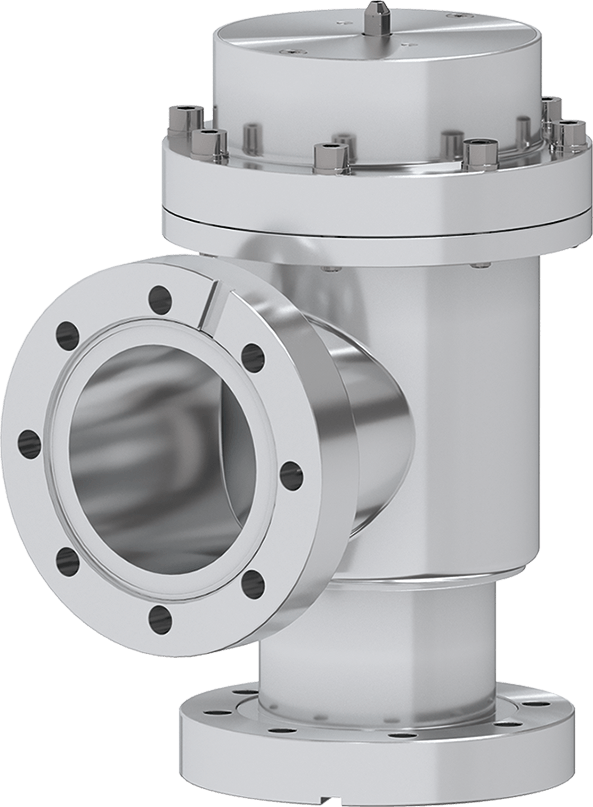

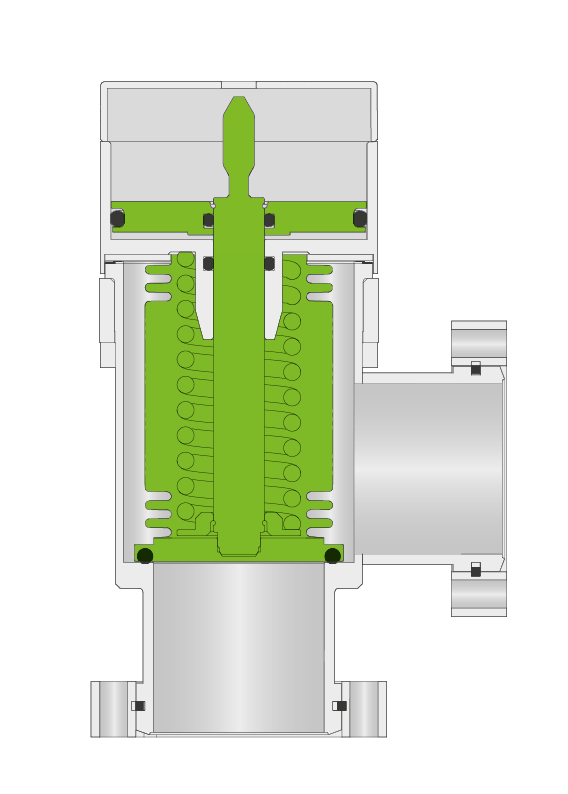

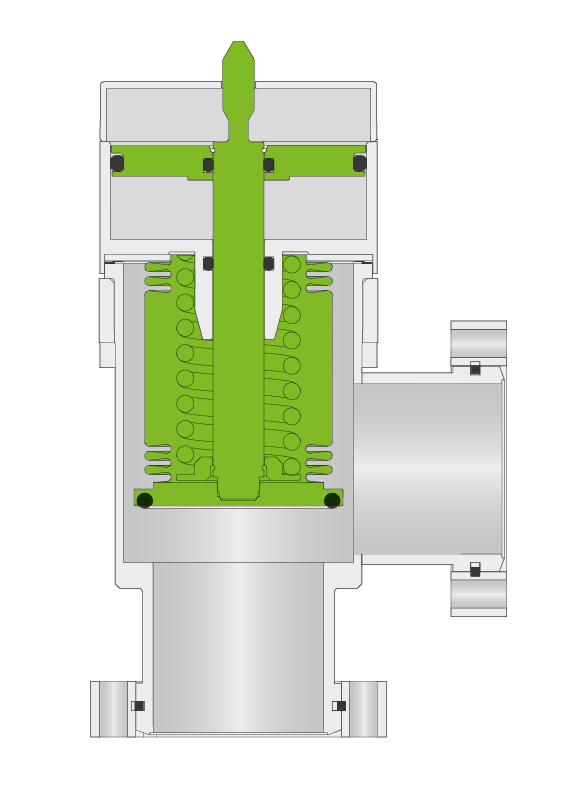

Read moreThe main requirements of an angle valve in UHV applications are reliable performance, the rate of particle emission and activation, and the outgassing rate. The 28.4 UHV Angle Valve series sets the standard in these areas. The series has been designed to reduce particle emission and activation and outgassing to a minimum.

Fitted with stationary rotatable CF-flanges and bonnet metal seals the valve series is suited for bake-out temperatures up to 200°C in the manual version and up to 150°C in the pneumatically actuated version.

The 28.4 is ideal for the pumping and venting of vacuum systems. It resists high differential pressure. Tested in thousands of demanding applications under various process conditions the 28.4 series has proven its outstanding reliability in UHV applications.

Based on a reliable and robust core design the 28.4 UHV Angle Valve offers manual or pneumatic actuation in sizes from DN 16mm – 63mm (5/8” – 2½”).

The standard flange connector is CF-R, but customer specified flanges are possible. The 28.4 is sealed with a metal bonnet seal and an FKM seal at the plate although other materials for the plate seal are an option. The feedthrough is bellows sealed.

A visual position indication as well as an electrical indicator are standard. The valve can be controlled by a solenoid valve either “on board” or in a distant location if required.

In addition to these standard options, the valve can be further customized.

Features:

Benefits:

| Sizes | DN 16 (⅝"), DN 25 (1’’) DN 40 (1½’’), DN 63 (2½’’) | ||

|---|---|---|---|

| Actuator | Pneumatic | Single acting with closirng spring (NC) | |

| Manual | With Removable Handwheel | ||

| Body Material | Stainless Steel | ||

| Feedthrough | Bellows | ||

| Standard Flanges | CF-R | ||

| Leak Rate | Valve Body | < 5 × 10-10 mbar ls-1 | |

| Valve Seat | < 1 × 10-9 mbar ls-1 | ||

| Pressure Range | 5 × 10-10 mbar to 5 bar (abs) | ||

| Differential Pressure on the Plate | In Opening Direction | ≤ 2 bar | |

| In Closing Direction | ≤ 5 bar | ||

| Differential Pressure at Opening | ≤ 1 bar | ||

| Cycles until first Service | 3 Million | ||

| Temperature | Valve Body | ≤ 150 °C | |

| Pneumatic Actuator | ≤ 150 °C | ||

| Manual Actuator | ≤ 120 °C | ||

| Solenoid Valve | ≤ 80 °C | ||

| Position Indicator | ≤ 80 °C | ||

| Material | Valve Body DN 16, 40 DN 63 |

AISI 304 (1.4301) AISI 316L (1.4404, 1.4435) |

|

| Plate | AISI 316L (1.4404, 1.4435) | ||

| Bellows | AISI 316L (1.4404, 1.4435) | ||

| Seal | Bonnet | Metal | |

| Gate | FKM (Viton®) | ||

| Mounting Position | Any | ||

| Solenoid Valve | 24 VDC (others on request) | ||

| Position Indicator: Contact Rating | Voltage | 5 – 50 VAC/DC | |

| Current | 5 – 100 mA | ||

| Valve Position Indication | Visual (Mechanical) | ||