Electron Microscopy, Metrology, Inspection & Defect Review

The control of the vacuum environment used in the field of electron microscopy, metrology, inspection & defect review requires high-precision vacuum v...

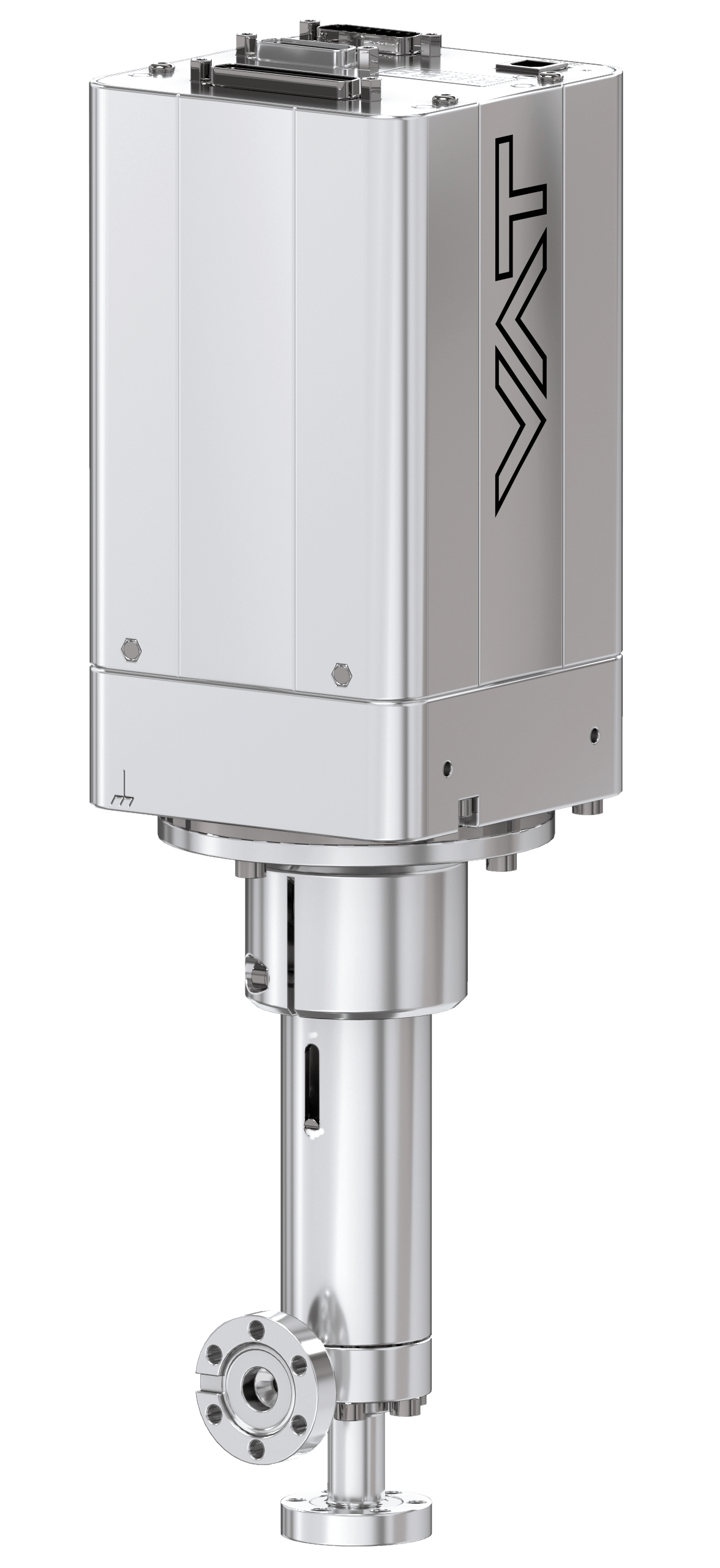

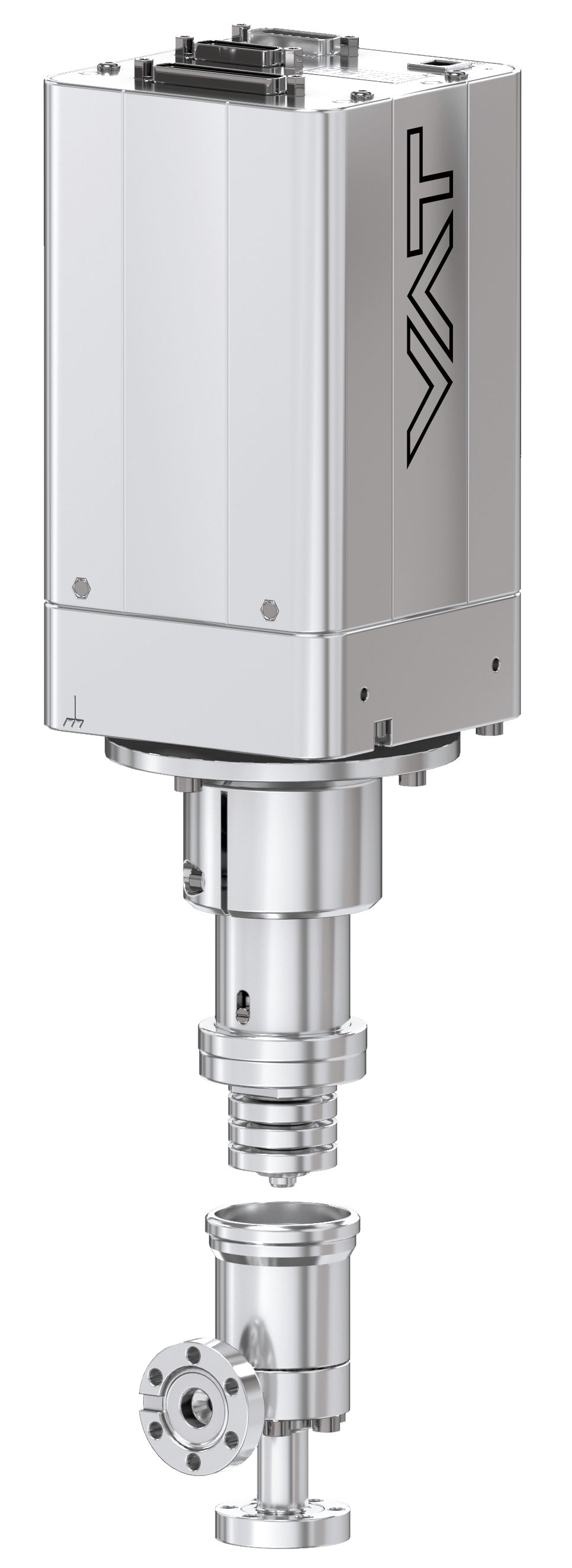

Read moreThe 59.0 UHV All-Metal Variable Leak Valve allows the precise control of very small gas flows (1· 10-10 mbar ls-1 to 500 mbar ls-1). With its full metal design it is ideal for gas dosing requirements in UHV and extreme UHV processes.

The special control function of the 59.0 guaranties a reproducible precise gas flow setting, enhancing process control capabilities. It also provides reliable, leak-tight closing over the whole life time, without any risk of sealing fatigue.

The full metal design – high grade SS valve body and gold plated SS membrane gate seal – gives the 59.0 also a high resistance against corrosive and aggressive gases.

Already installed in thousands of demanding applications under various process conditions, the 59.0 has proven its outstanding reliability. It has become the standard solution for variable leak valve in UHV and XHV applications.

The 59.0 is available in DN 16 mm (5/8”) as angle and as inline version, in manual actuation or with integrated or detachable pressure controller with stepper motor. With the detachable controller the 59.0 can be backed-out at max. 300 °C (with the controller detached). Standard flange is CF-R fixed in place.

The diaphragm’s “hard on hard” seal is designed for the full valve life time of 400 000 control cycles and 10 000 leak-tight closing cycles without needing any servicing although it is available as spare part and is easy replaceable.

| Sizes | DN 16 (⅝") | |||

|---|---|---|---|---|

| Actuator | Manual | Handwheel | ||

| Integrated or detachable pressure controller with stepper motor | ||||

| Body Material | Stainless Steel | |||

| Standard Flanges | CF-R | |||

| Sealing Technology | Diaphragm "hard on hard" sealing | |||

| Leak Rate | Valve Body | < 1 × 10-10 mbar ls-1 | ||

| Valve Seat | < 1 × 10-10 mbar ls-1 | |||

| Pressure Range | UHV to 10 bar (abs) | |||

| Differential Pressure | At Opening | ≤ 10 bar | ||

| Dead Volume | Angle Valve: | Seat Side Side Port | 2.7 cm3 1.1 cm3 | |

| Inline Valve: | Seat Side Side Port | 0.98 cm3 1.01 cm3 | ||

| Cycles until first Service | 20 000 | |||

| Bake-Out Temperature | Valve Body | ≤ 300 °C | ||

| Manual Actuator | ≤ 300 °C | |||

| Controller with Stepper Motor | ≤ 50 °C | |||

| Heating and Cooling Rate | ≤ 60 °C h-1 | |||

| Material | Valve Body | AISI 660 (1.4943), AISI 316L (1.4404) | ||

| Diaphragm | AISI 301 (1.4310), gold-plated | |||

| Mounting Position | Any | |||

| Valve Position Indication | Visual (Mechanical) | |||

| Conductance (Molecular Flow) | 0.05 ls-1 | |||

| Adjustable Gas Flow | 1 × 10-10 mbar ls-1 to 500 mbar ls-1 | |||

| Weight | With Manual Actuator | 0.94 kg / 2.07 lbs | ||

| With Controlled Stepper Motor | 2.5 kg / 5.5 lbs | |||

If you have your specification already at hand, please upload it and submit it to us. We are happy to send you a quote.