Synchrotrons & Accelerators

Synchrotrons and accelerators usually operate with large vacuum volumes in the UHV or XHV range. Having high demands on a physically inert behavior of...

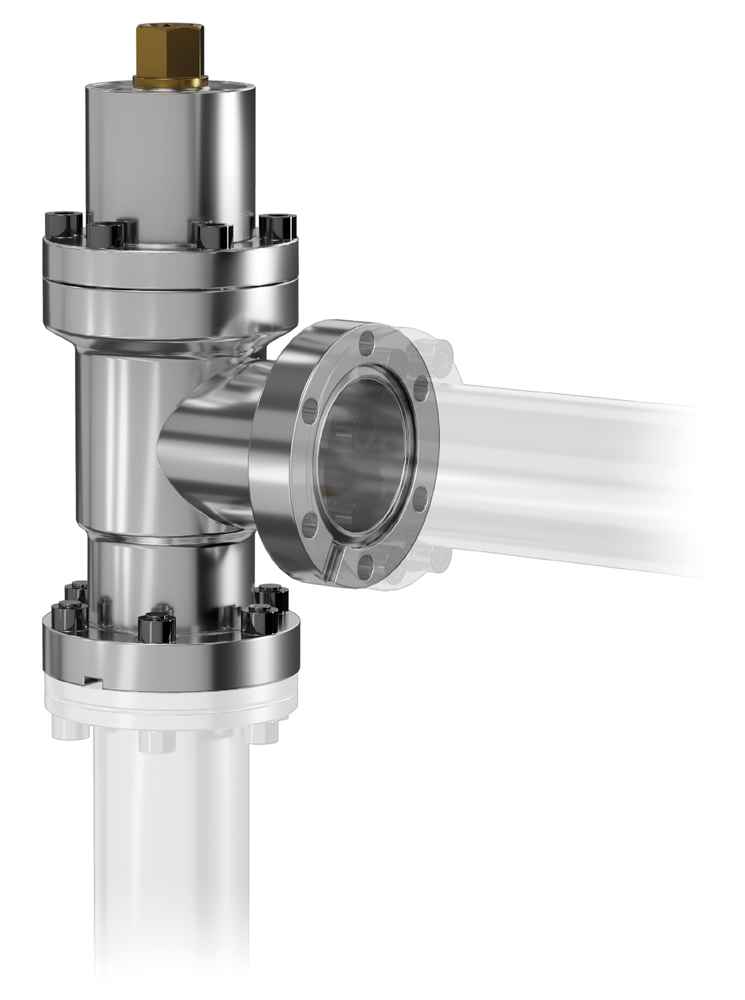

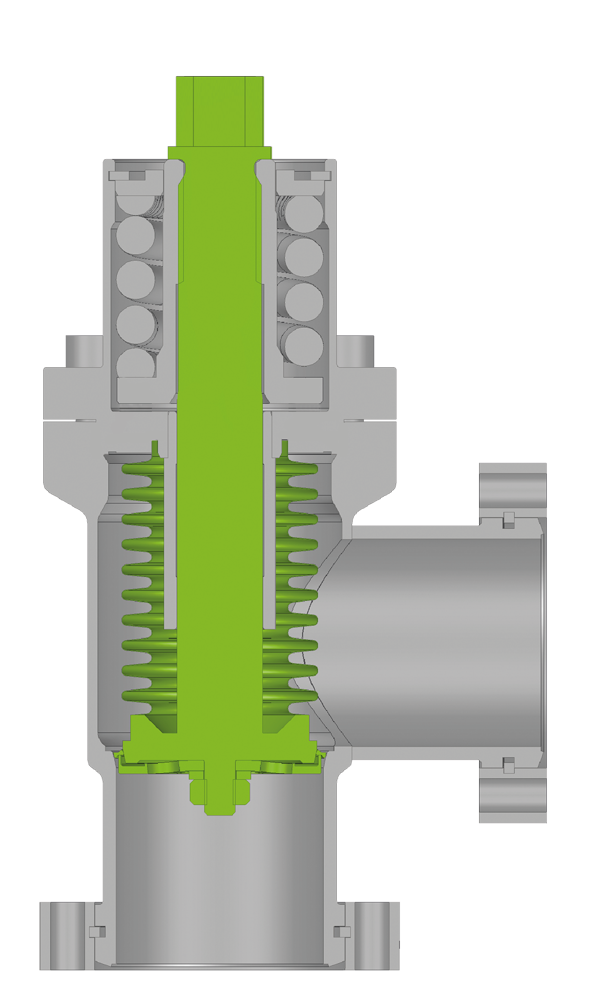

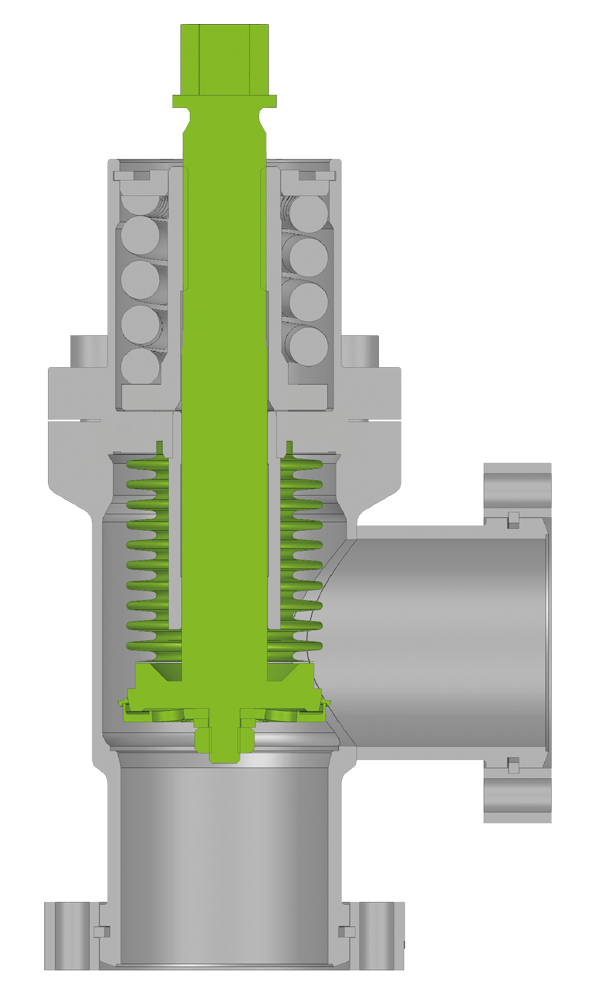

Read moreThe 54.1 All-Metal Angle Valve is equipped with FLEX VATRING, a “hard on hard” sealing technology. This dynamic, all-metal sealing system is characterized by consistent sealing and constant closing forces. It enables high sealing forces with comparable low axial forces. The sealing partners are made from stainless steel and they are deformed elastically only. The FLEX VATRING is easily exchangeable on side. It may be baked to 300 °C in open and close position and is capable of a lifetime of over 1000 cycles when operated under clean conditions.

Already installed in thousands of demanding applications under various process conditions, the 54.1 series has proven its outstanding reliability. It has become the standard solution for vacuum isolation in UHV and XHV applications.

No torque wrench is required as the valve is easy to operate with a standard hexagon wrench. With its robust design and a high conductance the valve is suitable for many different vacuum applications.

A key feature of the 54.1 series is that the FLEX VATRING all-metal seal is easy to replace when the seal has worn out. While “hard-on-hard” all-metal seals often require re-machining of the valve seat, the 54.1 valve series is designed so that the replacement FLEX VATRING seals in a new area of the valve seat rather than in the same position as the former ring seal. The FLEX VATRING can be replaced twice due to its three-level sealing seat.

The standard flange is CF-R fixed in place.

| Sizes | DN 16 (⅝"), DN 40 (1½"), DN 63 (2½") | ||

|---|---|---|---|

| Actuator | Manual | Hexagon Head | |

| Body Material | Stainless Steel | ||

| Feedthrough | Bellows | ||

| Standard Flanges | CF-R | ||

| Leak Rate | Valve Body | < 1 × 10-10 mbar ls-1 | |

| Valve Seat | < 1 × 10-10 mbar ls-1 | ||

| Pressure Range | XHV to 2 bar (abs) | ||

| Differential Pressure on the Plate | ≤ 2 bar | ||

| Differential Pressure at Opening | ≤ 1 bar | ||

| Lifetime | ≥ 1 000 Cycles | ||

| Bake-Out Temperature | in open and closed position | ≤ 300 °C | |

| Heating and Cooling Rate | ≤ 60°C h-1 | ||

| Material | Valve Body | AISI 316L (1.4404, 1.4435) | |

| Mechanism | AISI 316L (1.4404, 1.4435) | ||

| Bellows | AISI 316L (1.4404, 1.4435) | ||

| Seal | Bonnet | Metal (Silver Plated) | |

| Gate | Metal (Silver Plated) | ||

| Mounting Position | Any | ||

| Valve Position Indication | Visual (Mechanical) | ||

| Conductance (Molecular Flow) | DN 16 DN 40 DN 63 |

5 ls-1 50 ls-1 105 ls-1 |

|

| Closing Force | Closes at a mechanical stop | ||

| Weight | DN 16 DN 40 DN 63 |

0.4 kg / 0.9 lbs 1.9 kg / 4.2 lbs 5.9 kg / 13 lbs |

|

Shooting an underground movie of real life Switzerland has a long tradition in underground engineering and is world-renowned for the construction of t...

The Institute of High Energy Physics (IHEP) is China’s largest research institute for high energy physics. At IHEP, more than 1400 full-time employees...

Light has always been the most important tool for humanity to advance the understanding of nature. We only tend to believe what is visible to our eyes...