Sputtering

PVD sputtering is a core process in display production. An important manufacturing step is, for example, backplane metallization, in which conductive...

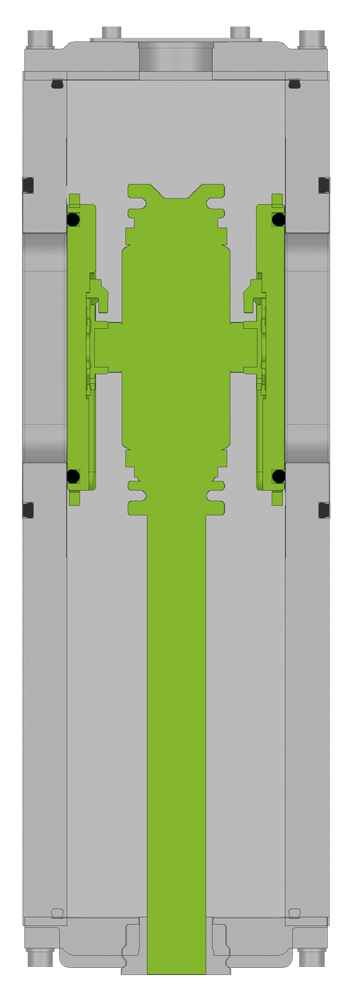

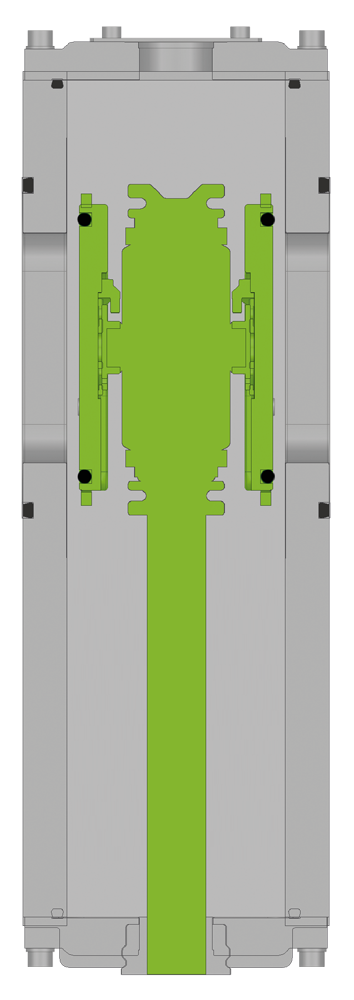

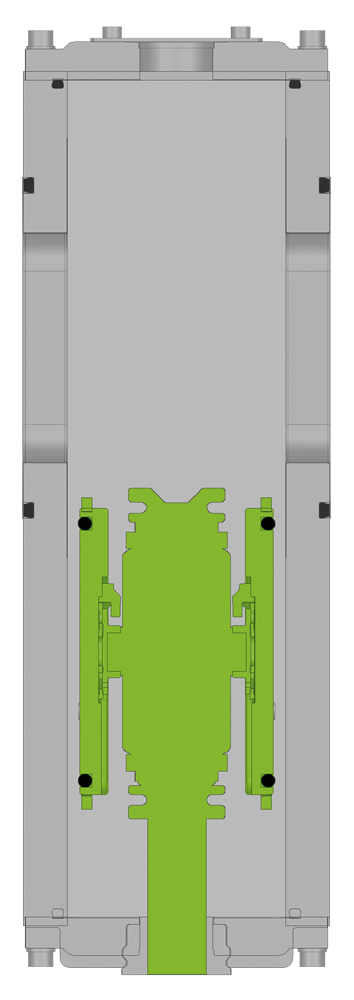

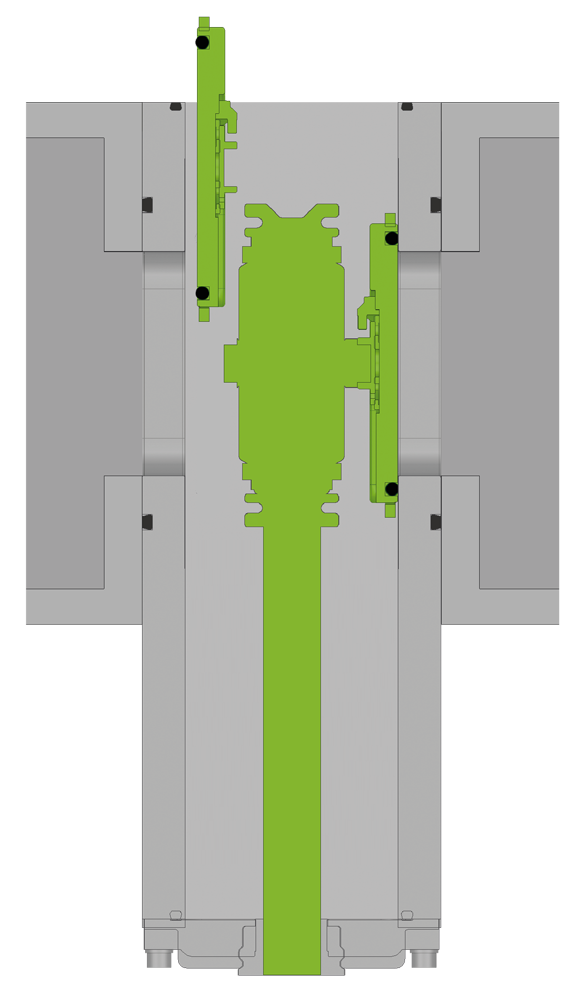

Read moreThe 06.1 Large Transfer Valve / Insert with TWINVAT has been developed to meet the special requirements of display production systems. Developed for high cycle production systems, the 06.1 combines virtually particle-free operation at an outstanding fast motion time for large transfer valves (≤ 2 s with 150 mm opening height). The 06.1 is designed for a high uptime and reliable operation over a lifetime beyond one million cycles.

The TWINVAT technology used for the 06.1 is based on a modular platform concept and fully optimized for the key display applications:

The 06.1 series is available as standard transfer valve with housing or as insert version to be mounted directly into the process chamber.

Already installed in hundreds of display production systems around the world under various process conditions, the 06.1 series has proven its outstanding performance in all aspects.

The 06.1 Large Transfer Valve / Insert with TWINVAT is tailored to the exact customer specification like all VAT transfer valve solutions. These customizations can include an additional process control unit, special surface treatments like hard anodized or nickel-plated aluminum, other sealing materials, vacuum gauges to detect the pressure in the valve body, bellows protected shaft feedthrough, RF & DC grounding options for valve and gate, lateral mounting position of the actuators and more.

| Sizes | 100 x 1000 mm to 300 x 3800 mm (3.94" x 39.37" to 11.81" x 149.60") | ||

|---|---|---|---|

| Actuator | Pneumatic | Double acting with position indicator | |

| Body Material | Aluminum | ||

| Feedthrough | Shaft Feedthrough | ||

| Leak Rate | Valve Body | < 1 × 10-7 mbar ls-1 | |

| Valve Seat | < 1 × 10-7 mbar ls-1 | ||

| Differential Pressure | On the Gate | Valve: in closing direction only | ≤ 1 bar |

| Insert: in opening direction | ≤ 30 mbar | ||

| At Opening | ≤ 5 mbar | ||

| Cycles until first Service | 1 Million | ||

| Closing or opening time | < 2.5 s (with 150 mm opening height) | ||

| Temperature | Valve Body, Gate | ≤ 120 °C | |

| Actuator | ≤ 60 °C | ||

| Solenoid Valve | ≤ 50 °C | ||

| Material | Valve Body, Gate | EN AW-6082 (3.2315) or EN AW-5083 (3.3547) | |

| Actuator Shafts | AISI 316 (1.4401) | ||

| Bellows on pressure element | AISI 633 (AM 350) | ||

| Seal | Gate, flanges, feedthrough, actuator | FKM (Viton®) | |

| Pump / Vent Port | ISO-KF 40 | ||

| Mounting Position | Actuator Up or Down | ||

| Position Indicator | Voltage | 24 V DC PNP (NPN optional) | |