Display Dry Etching

Typically, dry etching removes and etches a masked pattern of semiconductor material through an ion bombardment (usually a plasma of reactive gases) t...

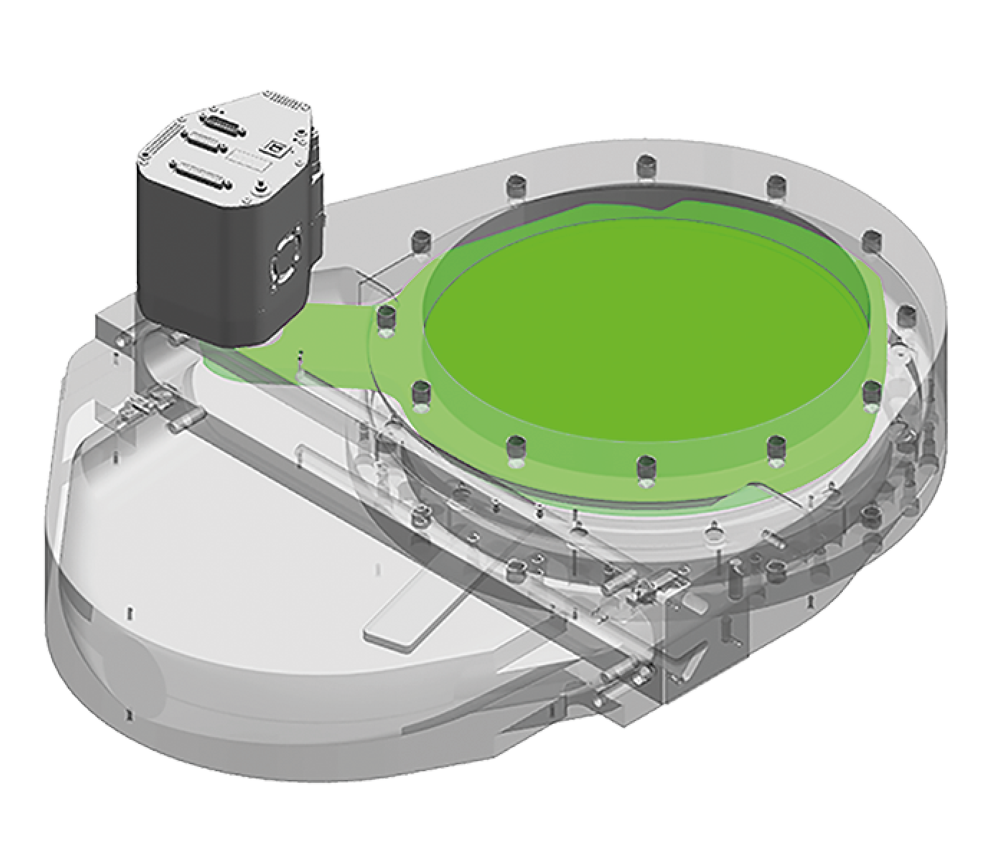

Read more65.3 the pressure swing control valve sets a new standard for downstream pressure control and isolation. This series of pressure swing control valves are specially designed for semiconductor and display production systems, which can provide the highest level of controllability in a wide range of conductance. 65.3 the pressure swing control valve is equipped with a motor with integrated position control, which can provide improved functions.

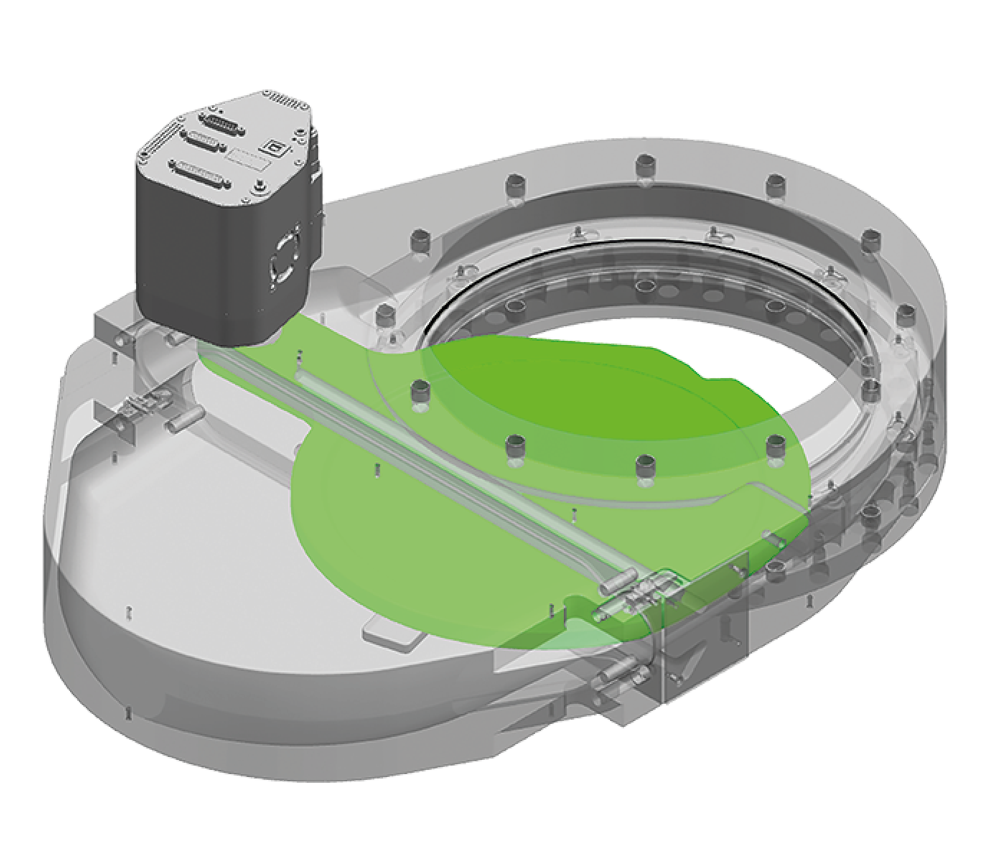

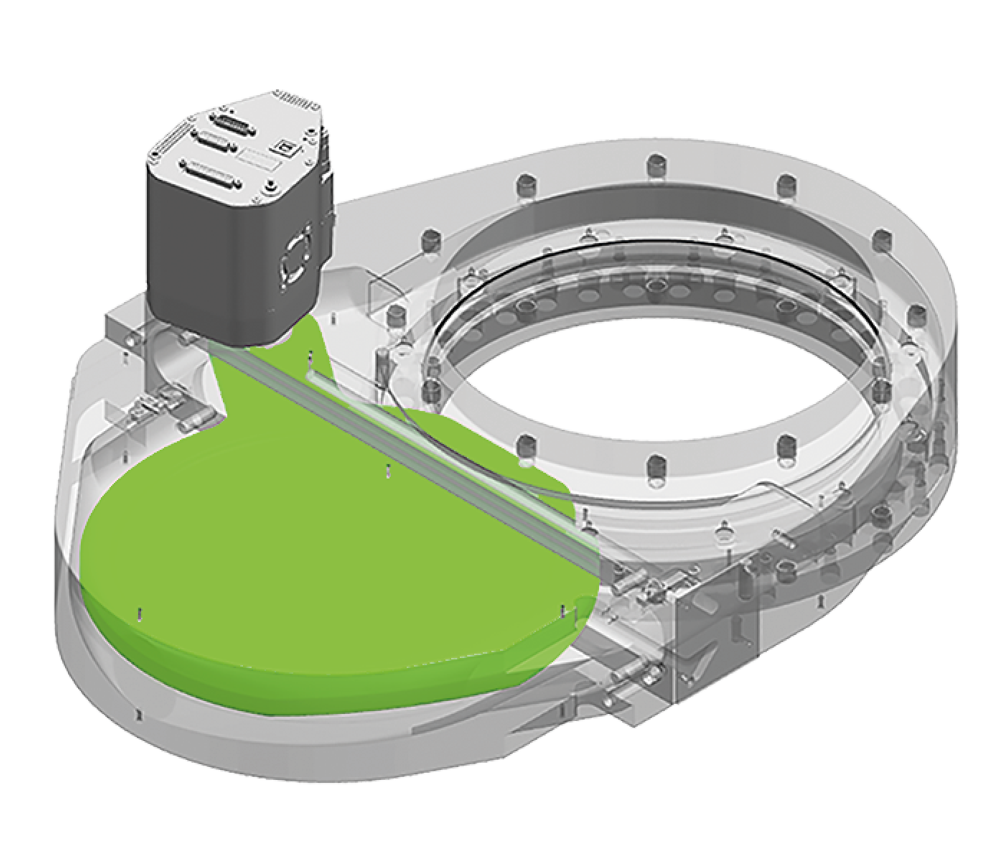

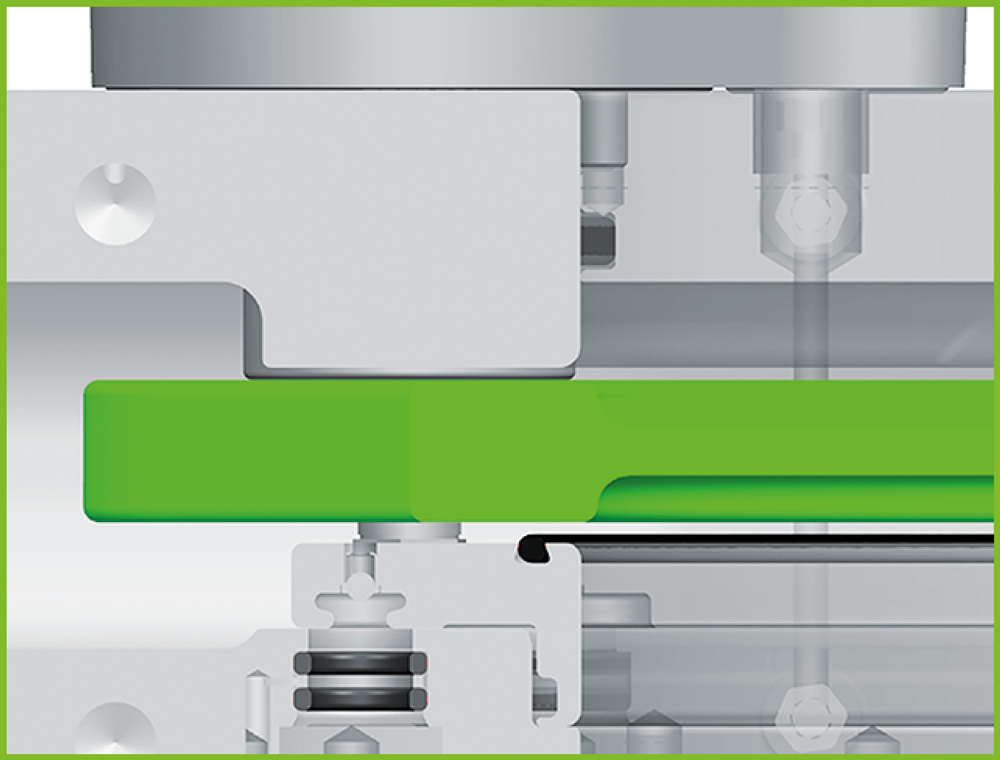

The driver controller has higher 32-bit data processing capability, which can provide new controllability. This means that each position of the pendulum valve plate can be controlled very quickly, precisely and accurately, so as to achieve very accurate downstream pressure control in a very short response time. The preset motion sequence of the valve can adjust the speed and route according to various constantly changing process parameters. 65.3 the pressure swing valve can also prevent the release of particles. The optimized damping closing motion of the valve plate can avoid the impact and vibration common to traditional valves. 65.3 the closing of the pressure swing control valve is smooth, and the closing and opening are almost imperceptible. The valve plate provides very precise mechanical guidance, ensuring contactless air flow control in reciprocating motion and achieving uniform sealing in all areas of sealing movement.

65.3 the pressure swing control valve has been installed in hundreds of demanding applications under various process conditions, proving its excellent reliability and performance. 65.3 the pressure control swing valve is also an ideal choice for reforming the existing system.

65.3 the size of the pressure swing valve is DN 100-350 mm (4 "- 14"), made of aluminum or hard anodized aluminum, with iso-f and JIS standard flange connections. Custom flanges can be integrated or as a direct mount option. The standard sealing material is fluororubber, and other materials can be used as required.

The controller can adopt special control algorithm (adaptive, fixed PID, upstream, soft extraction). Various standard ports on the controller can be easily accessed through a personal computer or connected to a process control unit (PCU). The dedicated control performance analyzer (CPA) software can easily calibrate the 65.3 pressure swing valve and simplify the maintenance plan

Features:

Benefits:

| Sizes | DN 100 (4"), DN 160 (6"), DN 200 (8"), DN 250 (10"), DN 320 (12"), DN 350 (14") |

||

|---|---|---|---|

| Actuator | Stepper motor with integrated pressure controller | ||

| Body Material | Aluminum blank or hard anodized | ||

| Feedthrough | Actuator Sealing Ring |

Rotary Feedthrough Shaft Feedthrough |

|

| Standard Flanges | ISO-F, JIS | ||

| Leak Rate Valve Body | Blank aluminium Hard anodized aluminium |

< 1 × 10-9 mbar ls-1 < 1 × 10-5 mbar ls-1 |

|

| Leak Rate Valve Seat | Blank aluminium Hard anodized aluminium |

< 1 × 10-9 mbar ls-1 < 1 × 10-4 mbar ls-1 |

|

| Pressure Range | Blank aluminium Hard anodized aluminium |

1 × 10-8 mbar to 1.2 bar (abs) 1 × 10-6 mbar to 1.2 bar (abs) |

|

| Cycles until first Service1) | Pressure Control Closing / Opening |

1 Million 200 000 |

|

| Temperature | Valve Body Controller |

≤ 120 °C Max. 50°C (≤ 35 °C recommended) |

|

| Material | Valve Body, Plate | EN AW-6061 (3.3211) | |

| Sealing Ring | EN AW-6061 (3.3211), AISI 305 (1.4303), AISI 420C (1.3541), AISI 631 (1.4568) |

||

| Other Parts | AISI 316L (1.4404, 1.4435), AISI 440 (1.4122), AISI 301 (1.4310), AISI 316 Ti (1.4571), AISI 304 (1.4301) |

||

| Seal | Bonnet, Plate Body Feedthrough | FKM (Fluoroelastomer) | |

| Mounting Position | Any | ||

1) Maximum values depending on operating conditions and sealing materials