Thin Film Coating

A number of different processes are used for thin film coating processes, e.g. CVD, PVD, MOCVD or PECVD. All processes have in common that they take p...

Read moreThe 15.1 HV Isolation Gate Valve series has been specifically designed for applications where low particle generation and shock sensitivity are required. The valves can be used for vacuum isolation at various pressure levels up to UHV < 10-10 mbar.

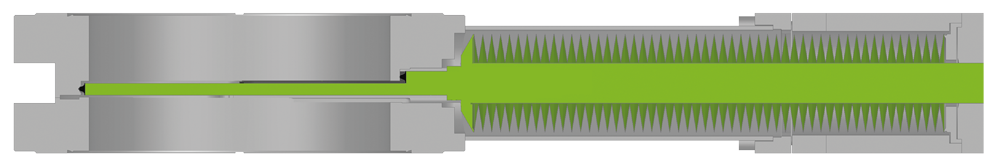

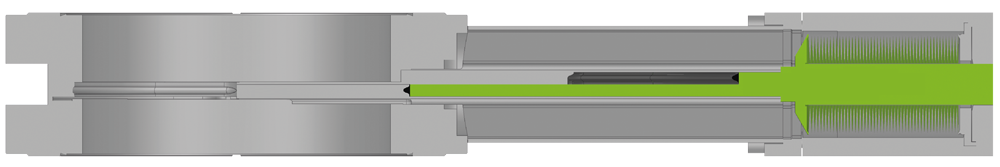

All valves in the series are equipped with MONOVAT technology. The technology provides reliable gate sealing without any friction and a reduced risk of particle generation. A key feature of the MONOVAT technology is the vulcanized gate seal. This is a highly reliable and more durable sealing solution. An additional benefit is its superior performance in terms of low particle generation and outgassing. Furthermore, the special soft closing mechanism of the MONOVAT technology – free of any lubricants – minimizes the mechanical shock effects to the system on which the valve is installed. In traditional valve solutions can mechanical shocks be caused by a fast moving gate touching the valve body.

Already installed in thousands of demanding applications, the 15.1 HV Isolation Gate Valve series has proven its outstanding reliability under various process conditions.

A robust design with a split body reduces efforts and simplifies maintenance. The series easily meets all requirements of vacuum isolation from standard vacuum to UHV.

Various design options in flange connections, sealing materials or additional vacuum ports make it easy to integrate into any application.

15.1 HV Isolation Gate Valves are available with pneumatic actuation and solenoid valves; either as an onboard solution or for external mounting. The standard voltage of solenoids is 24 VDC although other voltages are available on request. The valve position is indicated by mechanical or electrical position indicators, bakeable to max. 140 °C.

Flange connections ISO-F, CF-F (15.2), ASA-LP and JIS are standard options, as well as customer-

specific flanges. Customized features can be integrated, e.g. special gates with windows and foils or additional vacuum ports.

The valves are equipped with FKM seals. Other sealing materials are available on request.

Features:

Benefits:

| Sizes | DN 63 (2½’’), DN 100 (4"), DN 160 (6") | ||

|---|---|---|---|

| Actuator | Pneumatic | Double acting | |

| Body Material | Aluminum | ||

| Feedthrough | Bellows | ||

| Standard Flanges | ISO-F, ASA-LP, JIS | ||

| Leak Rate | Valve Body | < 1 × 10-9 mbar ls-1 | |

| Valve Seat | < 1 × 10-9 mbar ls-1 | ||

| Pressure Range | 1 × 10-8 mbar to 1 bar (abs) | ||

| Differential Pressure | On the Gate | ≤ 1.2 bar | |

| At Opening | ≤ 30 mbar | ||

| Cycles until first Service | 500 000 | ||

| Temperature | Valve Body | ≤ 120 °C | |

| Actuator | ≤ 100 °C | ||

| Solenoid Valve | ≤ 50 °C | ||

| Position Indicator | ≤ 80 °C | ||

| Heating and Cooling Rate | ≤ 30 °C h-1 | ||

| Material | Valve Body | EN AW-6082 (3.2315) | |

| Bellows | AISI 633 (AM350) | ||

| Seal | Bonnet, Gate | FKM (Viton®) | |

| Mounting Position | Any | ||

| Solenoid Valve | 24 VDC, 5.4 W (others on request) | ||

| Position Indicator: Contact Rating | Voltage | ≤ 250 VAC | ≤ 50 VDC |

| Current | ≤ 2 A | ≤ 1.2 A | |

| Valve Position Indication | Visual (Mechanical) | ||