Process Control & Isolation

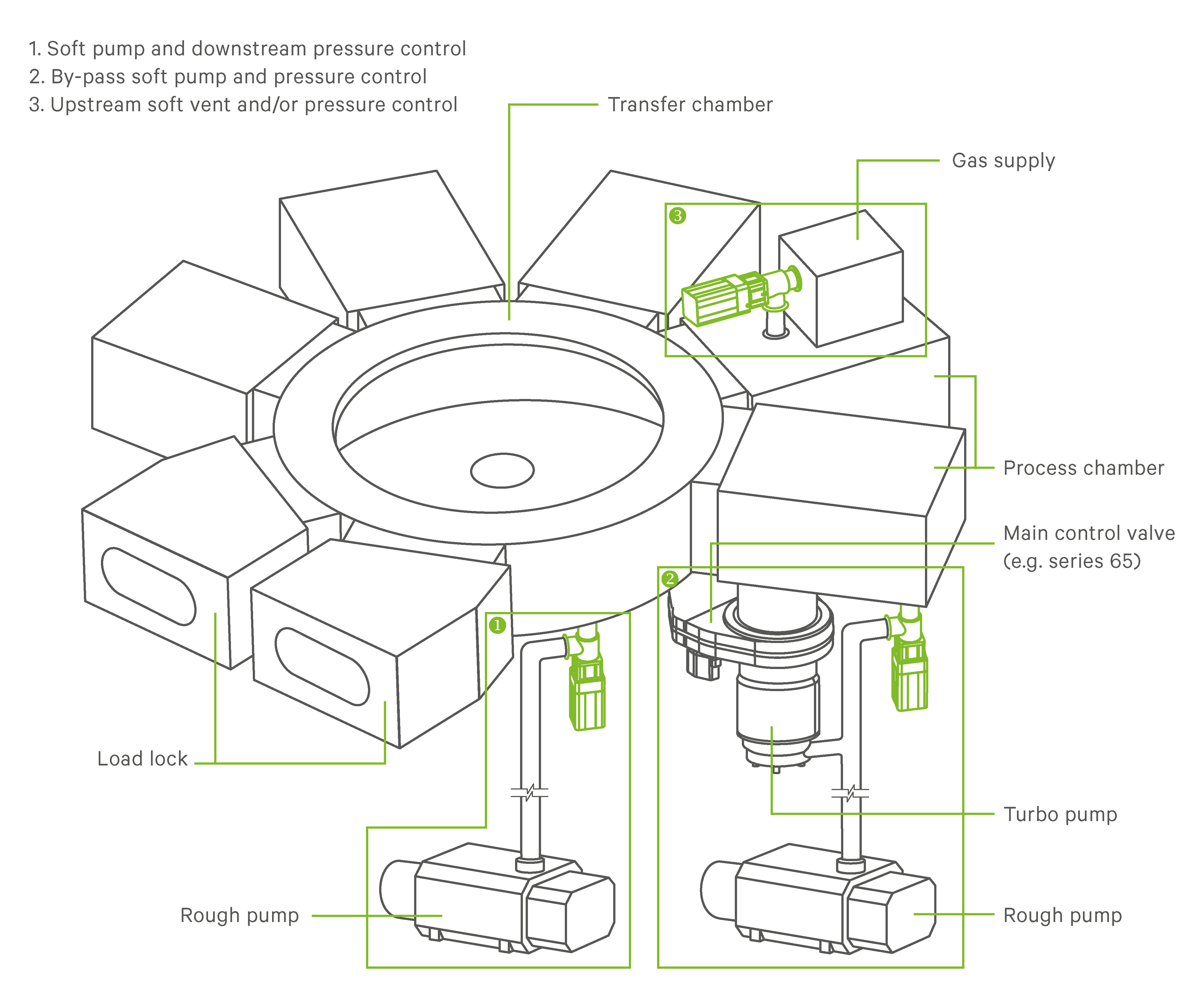

High-precision control and isolation of vacuum and gas flows is essential in semiconductor manufacturing. In both upstream and downstream processes, a...

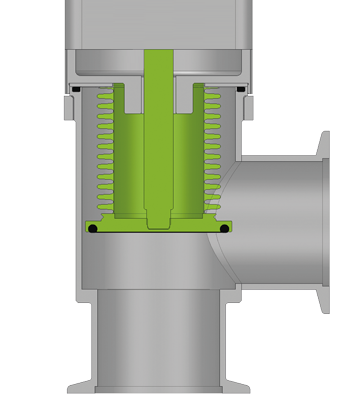

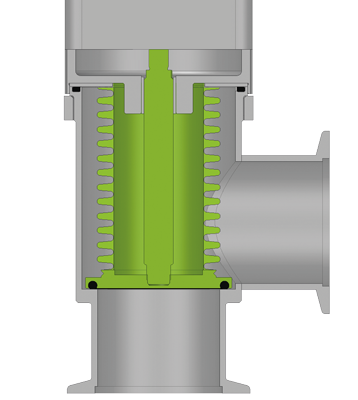

Read moreThe 62.0 Angle Control Valve series is ideal for vacuum processes with high pressure and/or high temperature environments such as ALD or CVD. With an operational temperature maximum of 200 °C the 62.0 delivers exceptionally precise pressure control performance. Due to its electric linear driven actuator the opening and closing cycle can be operated with a very smooth and fine control with a low minimal conductance. An integrated soft pump control function adds to this by avoiding the pressure peaks associated with most of the conventional pneumatic driven actuators.

The on board controller (external controller for DN 80 and DN 100) provides service port connections and various interfaces to connect to PCUs. A key feature of the valve controller is also a Control Performance Analyzer App through which the performance of the valve can be analyzed for various process conditions over time.

In the event of power loss, the 62.0 provides also a lock in “close” position function, which secures hermetic sealing of the valve.

Already installed in hundreds of demanding applications under various process conditions, the 62.0 Angle Control Valve has proven its outstanding reliability and performance. It sets the benchmark for angle control valve in terms of controllability and valve performance monitoring.

The 62.0 Angle Control Valve is available in sizes from DN 16 – 100 mm (5/8" – 4"). Its body material is stainless steel with the option of nickel-coating. Sizes DN 16 – 50 mm (5/8" – 2") are also available in aluminum. Bonnet and plate are FKM or FFKM sealed. The feedthrough is bellows sealed.

A heating jacket is an option, while a special bellows heating is an additional option for DN 80 and DN 100.

Controller interfaces are RS232, RS485, Logic (analog/digital), DeviceNet®, Profibus and EtherCAT.

Features:

Benefits:

| DN 40 (1 1/2"), DN 50 (2") | DN 100 (4") | ||

|---|---|---|---|

| Actuator | Linear Drive with closed loop controlled stepper motor | ||

| Body Material | Aluminum, Stainless Steel | Stainless Steel | |

| Feedthrough | Bellows | Bellows | |

| Standrad Flanges | ISO-KF | ISO-K | |

| Leak Rate | Valve Body | < 1 × 10-9 mbar ls-1 | < 1 × 10-9 mbar ls-1 |

| Pressure Range | < 1 × 10-8 mbar to 1.4 bar (abs) | < 1 × 10-8 mbar to 1.1 bar (abs) | |

| Differential Pressure | On the Plate at Opening | ≤ 1 bar | ≤ 1 bar |

| Cycles until First Service1) | Throttling Isolation |

2 Million 1 Million |

1 Million 200 000 |

| Temperature | Standard (Valve/Bellows) High Temperature Option (Valve/Bellows) Controller / Actuator Ambient |

≤ 80 °C ≤ 200°C max. 50 °C (≤ 35 °C recommended) |

≤ 80°C ≤ 200°C ≤ 50 °C (≤ 35 °C recommended) |

| Material | Valve Body, Plate Bellows |

aluminum EN AW-6082 (3.2315), AISI 316L (1.4404 or 1.4435) AISI 316Ti (1.4571) |

stainless steel 316L (1.4404 or 1.4435) AISI 316Ti (1.4571) |

| Seal | Bonnet, Plate | FKM (Viton®) | FKM (Viton®) |

| Mounting Position | Any | Any | |

1) Maximum values depending on operating conditions and sealing materials