Process Control & Isolation

High-precision control and isolation of vacuum and gas flows is essential in semiconductor manufacturing. In both upstream and downstream processes, a...

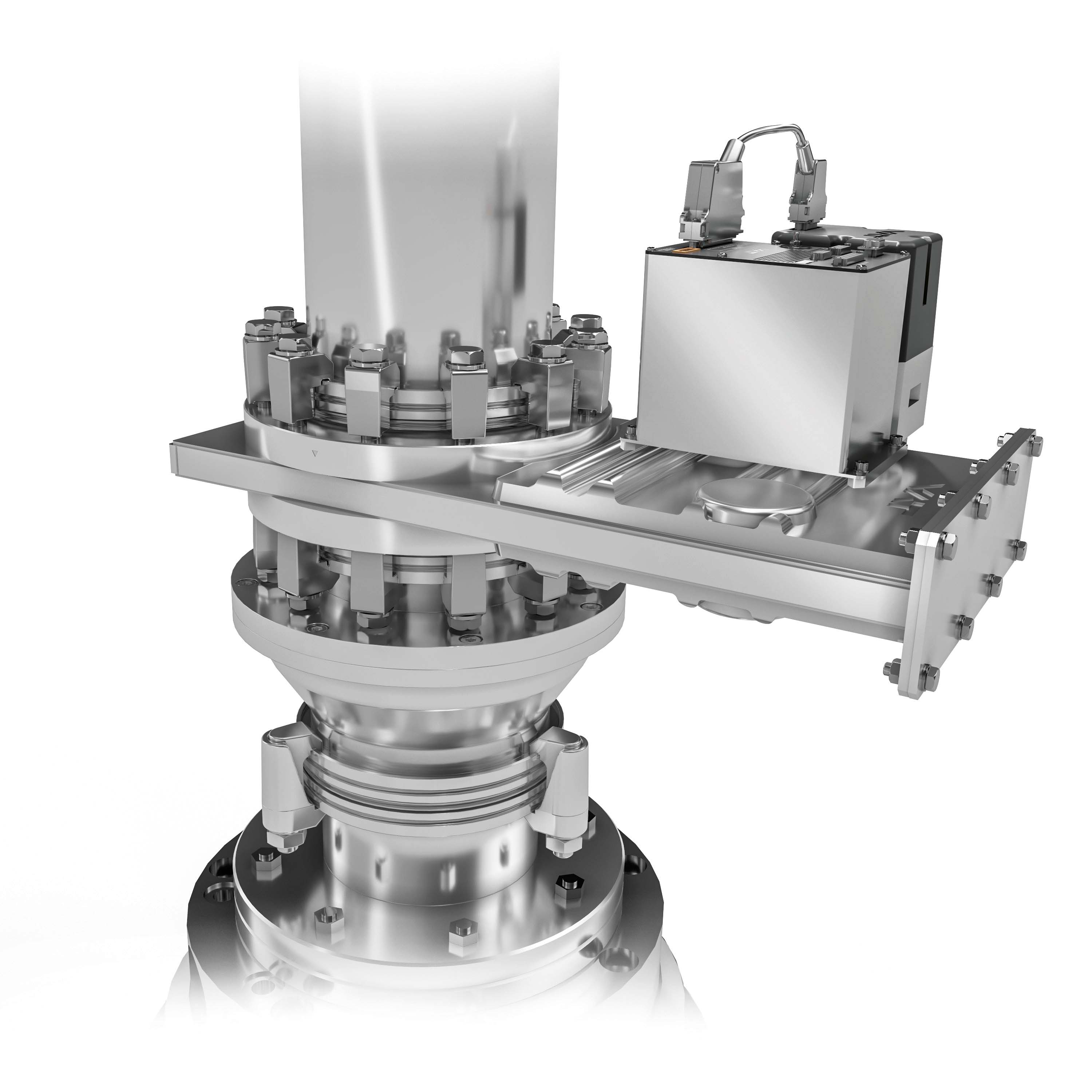

Read moreThe 64.2 HV Control Gate Valve is designed for reliable, precise control and isolation in high cycle vacuum processes such as sputtering or etching processes in semiconductor production. It addresses the standard requirements of durability, modularity and serviceability with a special focus on high uptime and low cost of ownership.

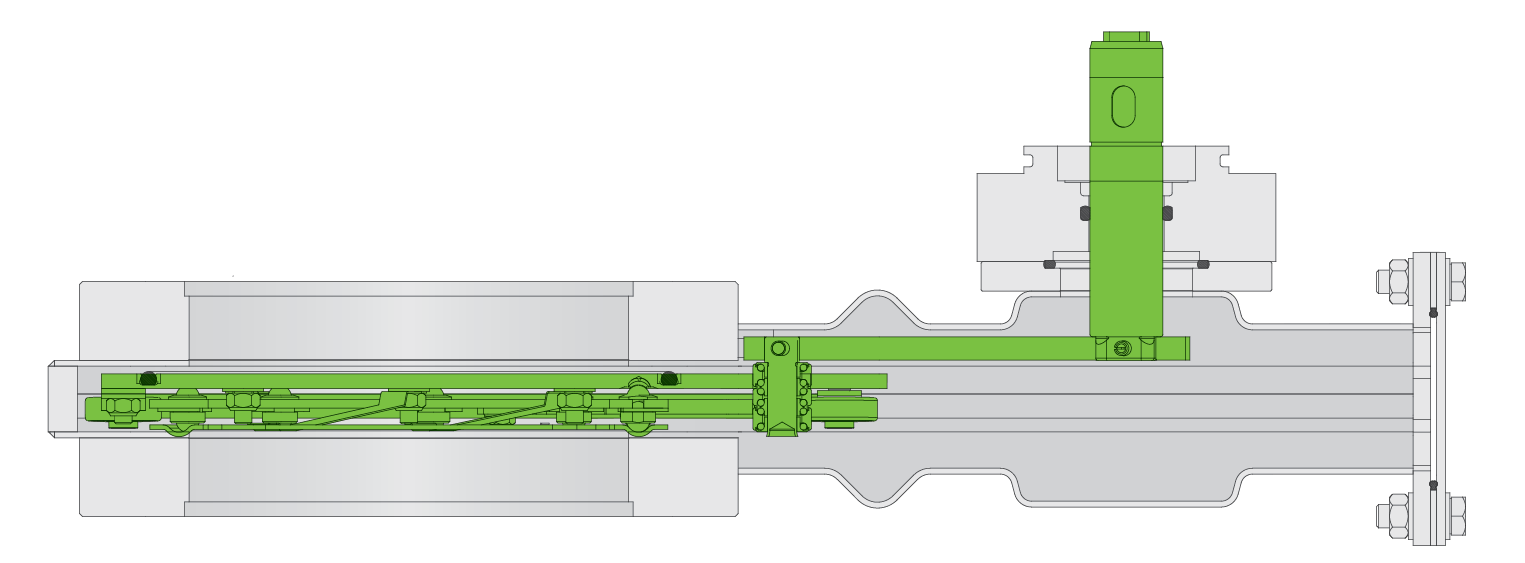

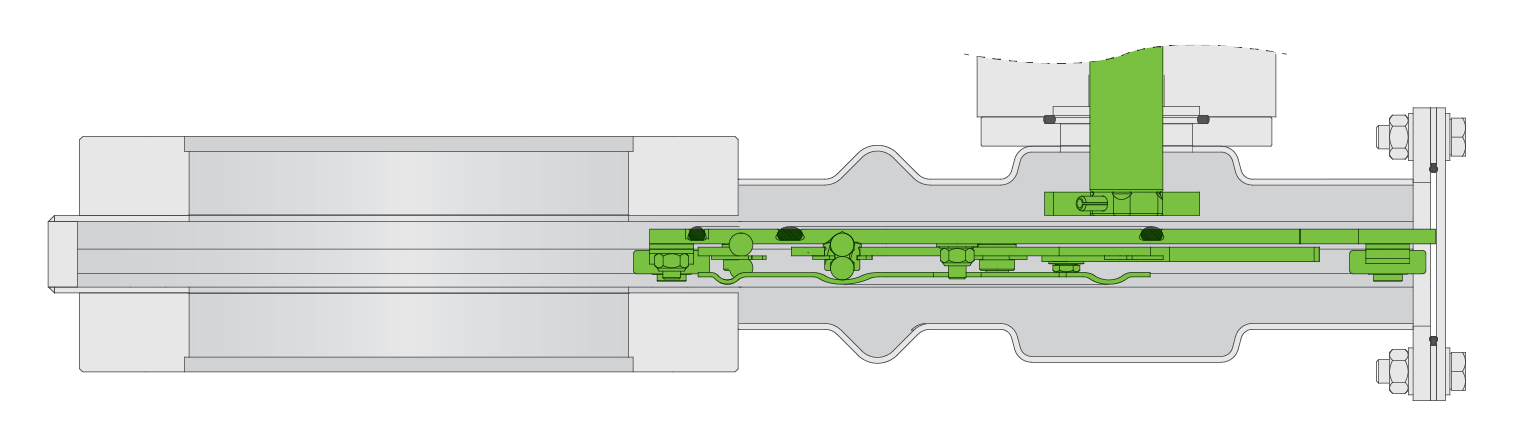

The 64.2 is equipped with VATLOCK technology which provides reliable sealing without any friction at the plate. The plate acts as a throttling element and varies the conductance of the valve opening. The onboard pressure controller calculates the required plate position to achieve the defined set point pressure. A stepper motor performs the actuation with an encoder monitoring the plate position. This ensures a fast and accurate process pressure control. The special VATLOCK lock-in mechanism in the close position guaranties leak tight isolation combined with failsafe closing in case of power loss.

Already installed in thousands of demanding applications under various process conditions, the 64.2 has proven its outstanding reliability. With its robust design it meets all of the requirements for a high cycle vacuum control gate valve.

To ensure optimal integration into a wide variety of vacuum applications, the 64.2 HV Control Valve is available in different design variants, including options in sealing material, flange connections, connections for roughing (by-pass), venting or gauges as well as special control algorithms (adaptive, fixed PI down-stream/soft-pump).

If the 64.2 needs to be fitted into limited mounting space, the actuator and controller can be mounted in different positions on the valve body. In addition, the controller can be installed detached from the valve actuator.

The series is available in sizes from DN 100 - 400mm (4” - 16”).

| Sizes | DN 100 (4"), DN 160 (6"), DN 200 (8"), DN 250 (10"), DN 320 (12"), DN 350 (14"), DN 400 (16") |

|

|---|---|---|

| Actuator | Integrated Pressure Controller with Stepper Motor | |

| Body Material | Stainless Steel | |

| Feedthrough | Rotary Feedthrough | |

| Standard Flanges | ISO-F, CF-F, ASA-LP/ASA, JIS | |

| Leak Rate | Valve Body, Valve Seat | < 1 × 10-9 mbar ls-1 |

| Pressure Range | DN 100 – 200 DN 250 – 400 |

1 × 10-8 mbar to 2 bar (abs) 1 × 10-8 mbar to 1.2 bar (abs) |

| Differential Pressure on the Gate (Closed) | DN 100 – 200 DN 250 – 400 |

≤ 2 bar ≤ 1.2 bar |

| Differential Pressure at Opening | ≤ 30 mbar | |

| Cycles until first Service1) | Pressure Control Closing / Opening |

1 Million 200 000 |

| Temperatur | Valve Body Controller |

≤ 150°C max. 50°C (≤ 35 °C recommended) |

| Material | Valve Body, Valve Gate | AISI 304 (1.4301) |

| Mechanism | AISI 301 (1.4310), AISI 304 (1.4301), AISI 420 (1.4034), AISI 420D (1.4037), AISI 430 (1.4016) |

|

| Seal | Bonnet, Gate, Feedthrough | FKM (Viton®) |

| Mounting Position | DN 100 – 350 DN 400 |

Any Horizontal |

| Valve Position Indication | Visual (Mechanical and on Controller) |

1) Maximum values depending on operating conditions and sealing materials