Vacuum Furnaces

In addition to the vacuum pumps used, the valve technology used in vacuum furnaces is decisive for process efficiency and quality. In addition to prec...

Read moreThe main requirements of a modern automated gas dosing valve are the degree of its controllability as well as its ability to reliably and precisely follow a predefined flow setting. The 62.7 Gas Dosing Valve series delivers both.

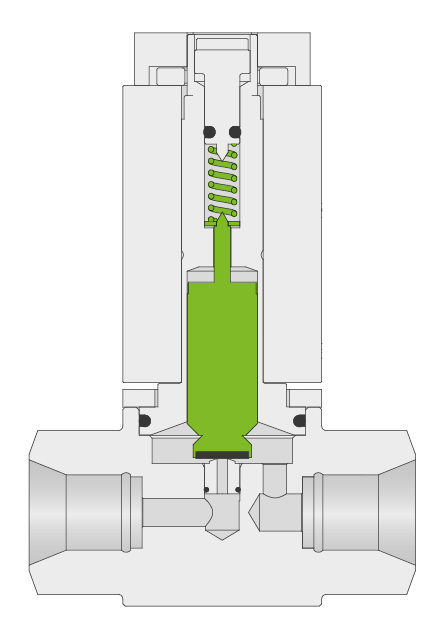

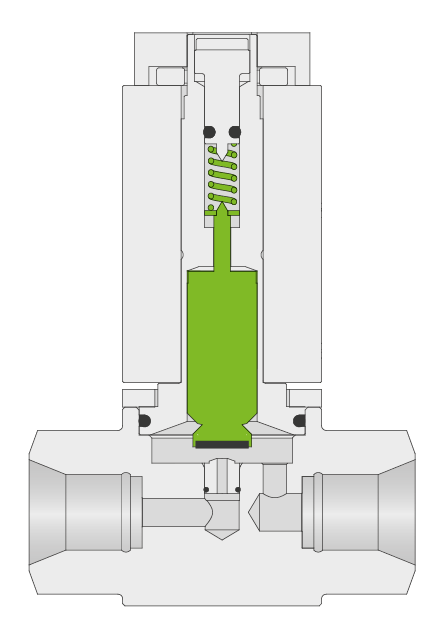

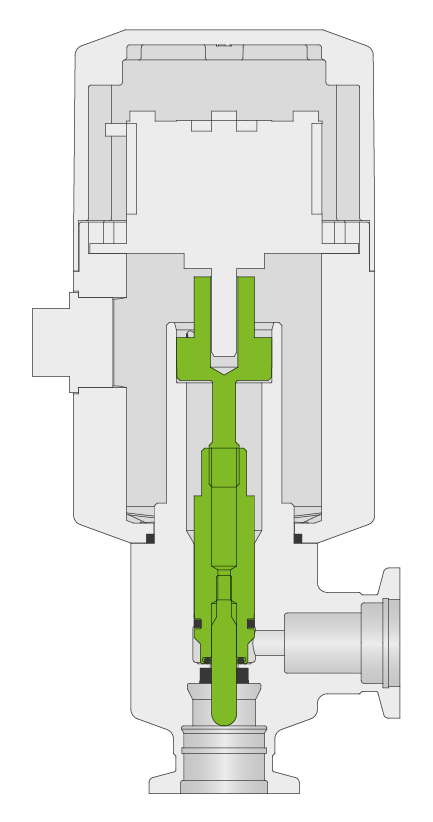

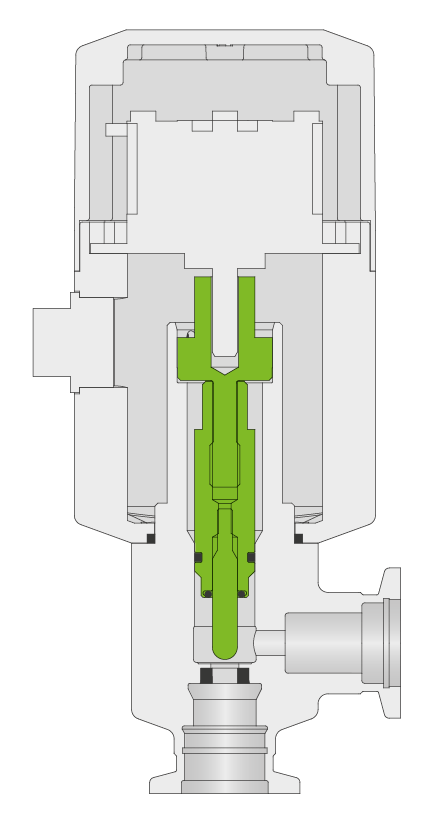

The 62.7 series is available in two different design versions: An electromagnetic actuated DN 5mm (3/16“) version and a stepper motor actuated DN 16mm (5/8“) version. Both versions are able to control the pressure in a range from < 1 · 10-8 mbar ls-1 to 2 bar (DN 5) and 2.5 bar

(DN 16) at any level in a very fine way. This means the flow characteristic from the initial opening to full conductance can be fully controlled at any pressure level. Not only does this mean that the 62.7 series is outstanding in its operational range, providing just one valve solution where normally several different valves would be needed. The series also provides unprecedented controllability. The special isolation and controlling system of the 62.7, a combination of a needle and plate mechanism for the DN 16 and an aperture and plate mechanism for the DN 5 allow very smooth opening characteristics that avoid any pressure change peaks even at very low conductance.

The chosen flow characteristic can be defined via a fixed setting or they can be operated in a dynamic setting where the 62.7 is connected via its controller to a pressure sensor in the process.

Tested in thousands of demanding applications under various process conditions, the 62.7 series has proven its outstanding performance.

DN 5

DN 16

The 62.7 Gas Dosing Valve is available in stainless steel with customer specific flanges for DN 5 and ISO-KF for DN 16. Gas flow characteristics can be directly defined on the external valve pressure controller via PC connection or via integration in a production process control unit (PCU).

Features:

Benefits:

| DN 5 mm (3⁄16") | DN 16 mm (⅝") | ||

|---|---|---|---|

| Actuator | Electromagnetic | Stepper Motor | |

| Body Material | Stainless Steel | Stainless Steel | |

| Feedthrough | Shaft Feedthrough | Shaft Feedthrough | |

| Standard Flanges | Specific | ISO-KF | |

| Leak Rate | Valve Body, Valve Seat | < 1 × 10-9 mbar ls-1 | < 1 × 10-9 mbar ls-1 |

| Pressure Range | < 1 × 10-8 mbar to 2 bar (abs) | < 1 × 10-8 mbar to 2.5 bar (abs) | |

| Differential Pressure on the Plate | ≤ 1.0 bar | ≤ 1.1 bar | |

| Temperature | Valve Body, Plate Ambient |

– 5 °C– 50°C |

≤ 150°C 5 °C–40°C |

| Material | Valve Body Plate |

AISI 316L (1.4404 or 1.4435) AISI 430IL (1.4105IL) |

AISI 316L (1.4404 or 1.4435) AISI 316L (1.4404 or 1.4435) |

| Seal | Plate Dosing Sleeve |

FPM – |

FPM Fluoropolymer |

| Mounting Position | Any | Any | |

| Controllable Conductance | Minimum/Maximum | 1.69 / 84.44 mbar ls-1 | 5 × 10-6 / 1250 mbar ls-1 |

| Operating Time | Closing / Opening | < 30 ms / < 30 ms | 3 s / 4 s |

| Power Supply | 24 VDC / 12 VA | 24 VDC / 12 VA | |

| Control | Digital with controller Analog 0…10VDC (max. 100 mA) |

Digital with controller Analog 0…10VDC (max. 100 mA) |

|

| Weight | 0.096 kg / 0.2 lbs | 0.8 kg / 1.8 lbs |