Electron Microscopy, Metrology, Inspection & Defect Review

The control of the vacuum environment used in the field of electron microscopy, metrology, inspection & defect review requires high-precision vacuum v...

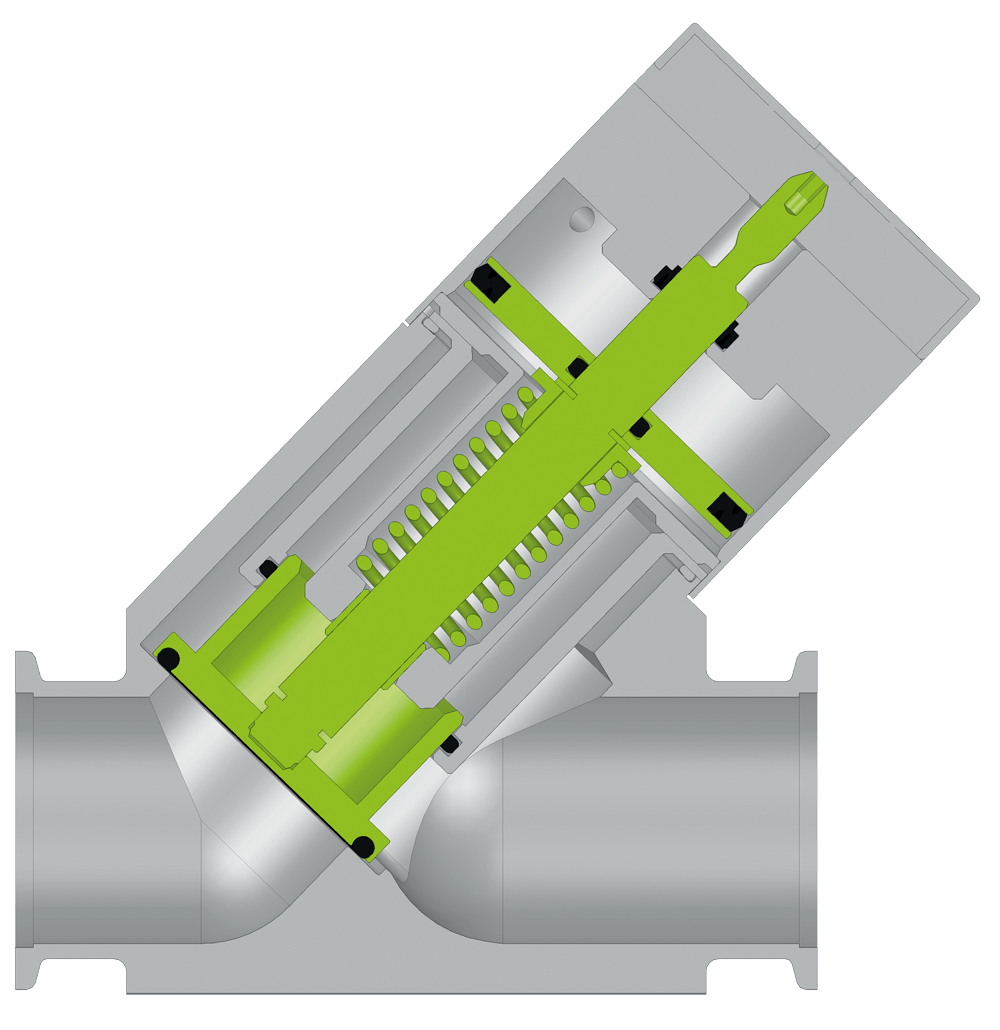

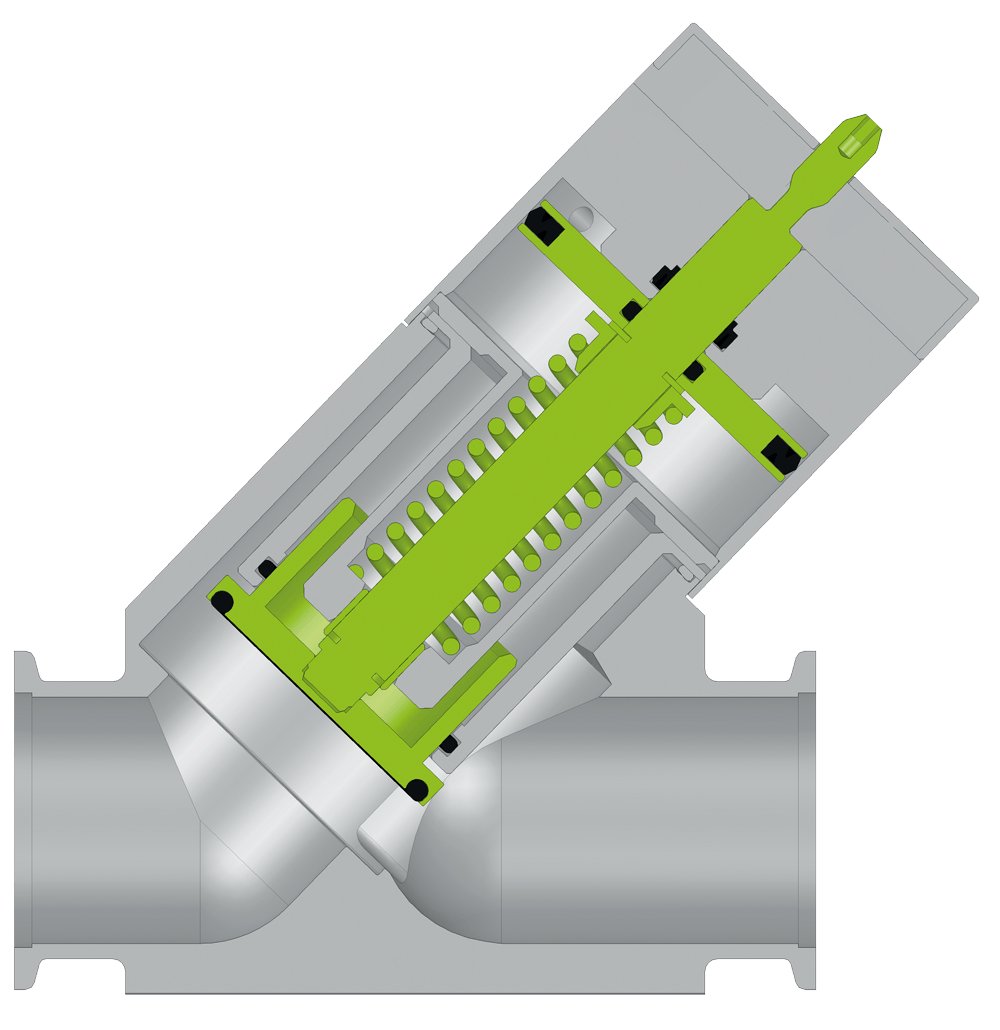

Read moreThe key performance indicators for angle valves are reliability and variability. The 24.5 Inline Valve series combines both. The series has been designed to allow the construction of large sizes for high and even slightly contaminated gas volume flows. Sizes of up to DN 800 mm (32") have been produced so far.

Tested in thousands of demanding applications under various process conditions the 24.5 series has proven its outstanding reliability. With its various design options in actuation, flanges connection, body material or sealing, nearly every requirement can be met.

The 24.5 is ideal for the pumping and venting of vacuum systems. It resists high differential pressure and its modular design means it can be adjusted to various process and operation requirements. The 24.5 is designed for outstanding reliability and a long lifetime.

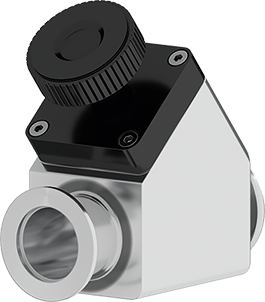

Based on a reliable and robust core design the 24.5 Inline Valve offers a high verity of design options for actuation from manual to pneumatic. In sizes from DN 10 to DN 800 mm (0.4" – 32") the 24.5 can be selected in aluminum or stainless steel in various specifications. The “all aluminum” solution provides advantages in selected applications with corrosive gases.

The standard options for flange connectors are ISO-KF and ISO-K. A visual position indication comes as standard although an electrical indicator can be added as an option. The valve can be controlled by a solenoid valve either “on board” or in a distant location if required. The 24.5 can be used in different temperature regimes depending on the sealing elastomer chosen. The valve can be supplied as normally opened, normally closed or double acting. In addition to these standard options further customization is possible.

Features:

Benefits:

| Sizes | DN 10 (⅜"), DN 16 (⅝"), DN 25 (1"), DN 40 (1½"), DN 50 (2"), DN 63 (2 ½") on request, DN 80 (3") on request |

|

|---|---|---|

| Actuators | Manual | With Removable Handwheel |

| Pneumatic | Single acting with Closing Spring (NC) or Single acting with Opening Spring (NO) or Double acting |

|

| Body Material | Aluminum or Stainless Steel | |

| Feedthrough | Shaft Feedthrough | |

| Standard Flanges | ISO-KF, ISO-K | |

| Leak Rate | Valve Body, Valve Seat | < 1 × 10-9 mbar ls-1 |

| Pressure Range | 1 × 10-7 mbar to 5 bar (abs) | |

| Differential Pressure on the Plate |

In Opening Direction |

≤ 2.0 bar ≤ 5.0 bar |

| Differential Pressure on the Plate | ≤ 1 bar | |

| Cycles until first Service | Manual Actuator Pneumatic Actuator |

10 000 3 million (NC, NO) |

| Temperature |

Valve Body |

≤ 150 °C ≤ 120 °C ≤ 80 °C |

| Material | Aluminium Stainless Steel Plate |

EN AW-6060 (3.3206), EN AW-6061 (3.3211), EN AW-6063 (3.3206), EN AW-6082 (3.2315) AISI 316L (1.4404) AISI 316L (1.4404, 1.4435) |

| Seal | Bonnet, Plate | |

| Mounting Position | Any | |

| Solenoid Valve | 24 VDC, 2.5 W (others on request) | |

| Position Indicator: Contact Rating |

Voltage |

5 – 50 VAC / DC 5 – 100 mA |

| Valve Position Indication | Visual (Mechanical) |