Thin Film Coating

A number of different processes are used for thin film coating processes, e.g. CVD, PVD, MOCVD or PECVD. All processes have in common that they take p...

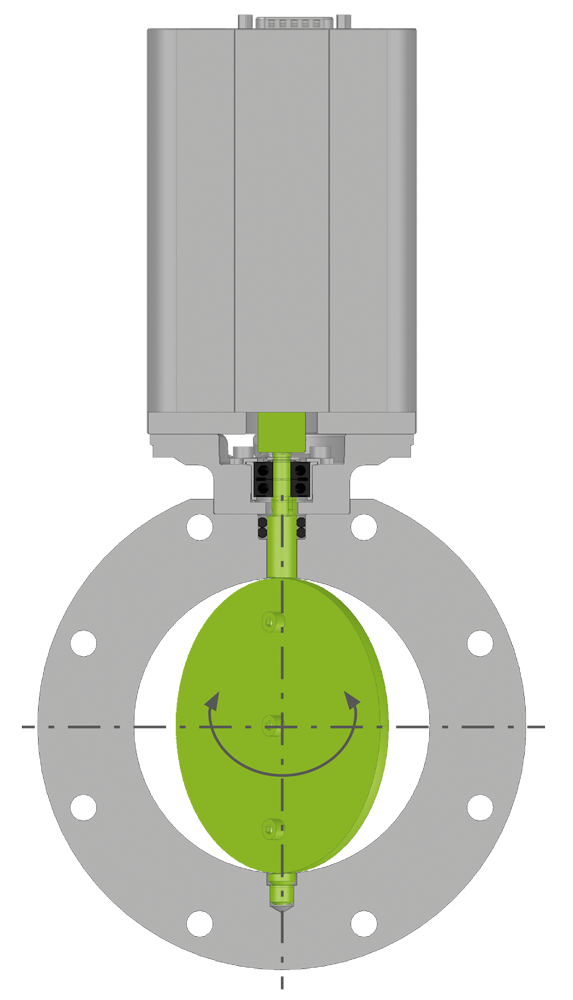

Read moreThe 61.3 HV Butterfly Control Valve provides outstanding pressure control performance. With its fast and precise acting motion controller (0.1 s) it’s the perfect solution for fine control in CVD and ALD processes. The plate acts as a throttling element and varies the conductance of the valve opening. The integrated pressure controller of the 61.3 calculates the required plate position to achieve the set pressure as fast as possible.

It is especially designed for harsh downstream processes with particle in the gas stream. The 61.3 stays fully operational despite high particle loads and debris accumulation by design.

Already installed in thousands of demanding applications under various process conditions, the 61.3 series has proven its outstanding reliability. With a robust design and direct mounting option, as well as reduced and easy maintenance, the 61.3 series convinces in all aspects.

Various design options in body material, surface treatment, elastomers, flange connections, special sizes as well as special control algorithms (adaptive, fix PI down-stream/soft-pump) simplify the integration into various vacuum applications.

61.3 HV Butterfly Control Valves is available in aluminum or stainless steel, with standard flange connectors in ISO-KF and ISO-F. Customer-specific flanges can be integrated as well as special features like an integrated heater with insulation. Various FFKM/FKM elastomers are available on request (FKM is standard).

Features:

Benefits:

| Sizes | DN 25 (1’’) DN 40 (1½’’), DN 50 (2’’), DN 63 (2½"), DN 80 (3"), DN 100 (4"), DN 160 (6"), DN 200 (8"), DN 250 (10"), DN 320 (12") |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Actuator | Integrated controller with Stepper Motor | ||||||||||||

| Body Material | Aluminum or Stainless Steel | ||||||||||||

| Standard Flanges | ISO-KF, ISO-F | ||||||||||||

| Leak Rate Valve Body | Aluminium | < 1 × 10-9 mbar ls-1 | |||||||||||

| Stainless Steel | < 1 × 10-9 mbar ls-1 | ||||||||||||

| Pressure Range | 1 × 10-8 mbar to 1.2 bar (abs) | ||||||||||||

| Cycles until first Service1) | Pressure Controll | 2 Million | |||||||||||

| Temperature | Valve Body Controller |

≤ 150 °C Max. 50°C (≤ 35 °C recommended) |

|||||||||||

| Material | Valve Body, Plate | Aluminium Stainless steel |

EN AW-6082 (3.2315) AISI 316L (1.4404 or 1.4435) |

||||||||||

| Shaft | AISI 316L (1.4404 or 1.4435) | ||||||||||||

| Seal | Feedthrough | FKM (others on request) | |||||||||||

| Feedthrough | Rotating shaft, direct driven | ||||||||||||

| Mounting Position | Any (shaft on pump side recommended) | ||||||||||||

| DN 25 | ... | DN 320 | |||||||||||

| Max. differential pressure | On the plate | 1000 mbar | ... | 75 mbar | |||||||||

| Conductance | Molecular flow | 22 ls-1 | ... | 27000 ls-1 | |||||||||

| Miniumum controllable conductance | Molecular flow | 0.15 ls-1 | ... | 6 ls-1 | |||||||||

| Typical closing or opening time "position only" version |

Aluminium, Stainless steel | 0.09 s | ... | 0.29 s | |||||||||

| Weight | Aluminium valve Stainless steel valve |

2.0 kg (4.40 lbs) 2.5 kg (5.5 lbs) |

... | 10.4 kg (23 lbs) 12.3 (27.1 lbs) |

|||||||||

1) Maximum values depending on operating conditions and sealing materials.