The National Institute of Standards and Technology (NIST) developed a quantum-based vacuum gauge – a cold atom vacuum standard (CAVS) device – that eliminates the shortcomings of conventional vacuum sensors. VAT all-metal vacuum valves – using durable VATRING technology – provide the necessary precision and reliability required by the innovative CAVS device for UHV/XHV product processes.

"As one of the oldest physical science laboratories in the USA, the NIST doesn't get into the news much," says Joshua LeBeau, Regional Sales Manager for VAT. "That's surprising, because providing a state-of-the-art measurement infrastructure is critical to innovations needed for future smart power grids, advanced nanomaterials, semiconductor chips and more."

Founded in 1901 and now part of the U.S. Department of Commerce, the National Institute of Standards and Technology (NIST) provides key services for measurements, standards, and legal metrology. The Institute’s guidelines and services ensure measurement traceability, enable quality assurance, and harmonize documentary standards, and regulatory practices – for use in research and industry.

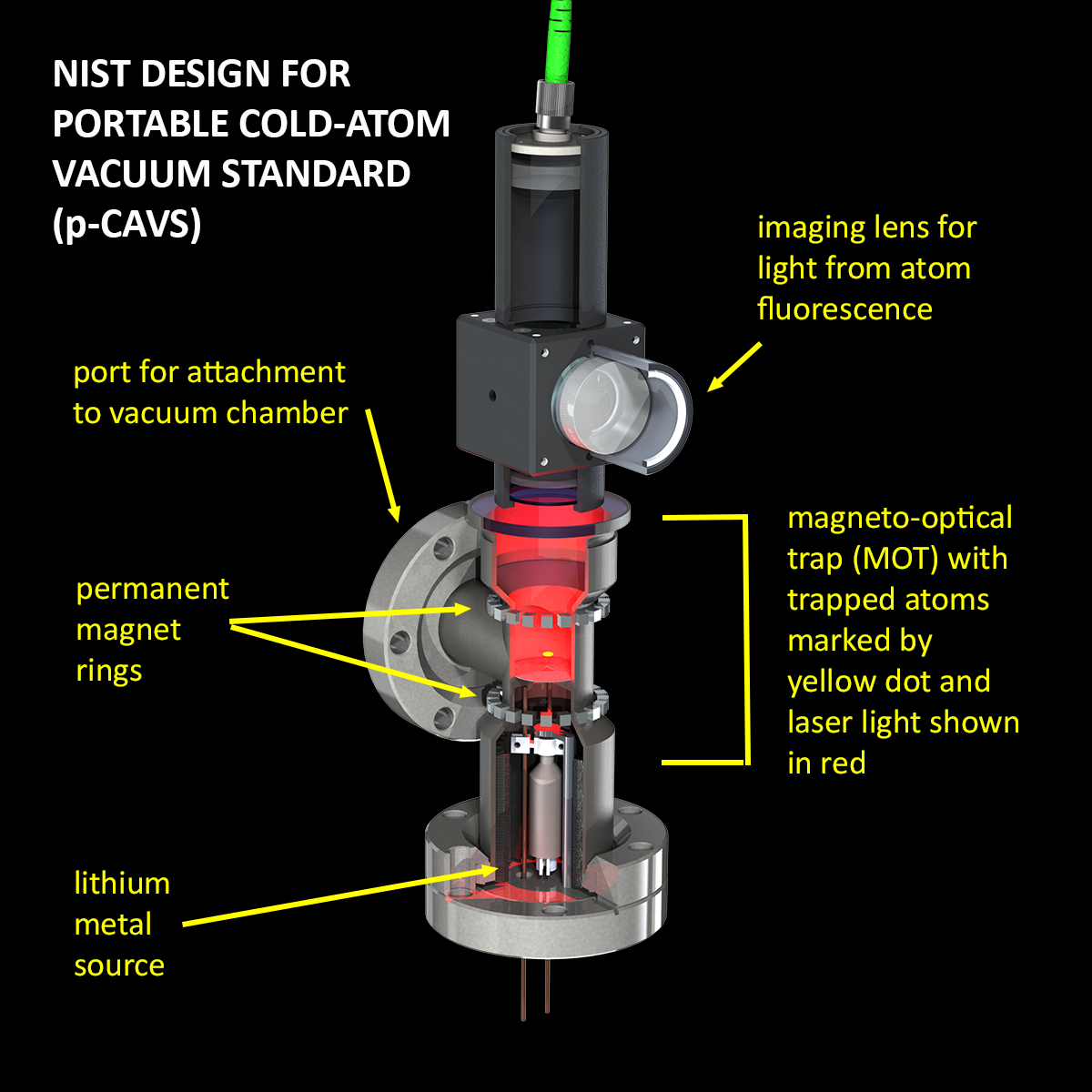

NIST scientists recently have designed a vacuum gauge that is small enough for use in a wide range of vacuum chambers. This gauge also meets quantum SI (International System of Units) criteria, meaning it requires no calibration, and depends on fundamental constants of nature to report the correct quantity or none at all, with specified uncertainties are suitable for measurement applications. This quantum-based vacuum gauge – a cold atom vacuum standard (CAVS) device – eliminates many of the shortcomings of conventional vacuum sensors while delivering much lower measurement uncertainties.

The CAVS is installed directly at the vacuum chamber in which the precision measurements are to be performed. At its core, it consists of an "atom trap" containing about 1 million ultracold alkali atoms that fluoresce when excited by a laser beam. The trapped atoms interact with the elements in the vacuum chamber, mainly hydrogen molecules, which remain after the chamber is pumped down to an ultrahigh (< 10-6 Pa) or extremely high

(< 10-10 Pa) vacuum level.

With each interaction, the number of alkali atoms decreases, reducing the amount of fluorescent light emitted. A sensor registers the attenuation. The faster the light decreases, the greater the number of elements remaining in the vacuum chamber. Consequently, the strength of the fluorescence is a precise measure of the pressure.

The UHV and XHV environments required in a wide variety of scientific and industrial fields must satisfy increasingly precise and constant framework conditions in order to be able to carry out specific, complex investigation and production processes in a controlled manner. For this purpose, precise pressure determination is indispensable.

“Conventional measurement technology for such high vacuum environments typically relies on an ionization gauge, which requires periodic recalibration and delivers +20% accuracy and is incompatible with modern SI standards,” explains Joshua LeBeau, U.S. National Sales Manager for VAT. “In contrast, CAVS needs no calibration and produces measurements that are consistently accurate, at around +1% for XHV applications.”

The NIST researchers who developed the CAVS incorporated VAT all-metal valves into their design. The durability and precision of the valves, along with the VATRING technology used, ensure that the CAVS can measure UHV and XHV pressure conditions, with repeatable reliability.

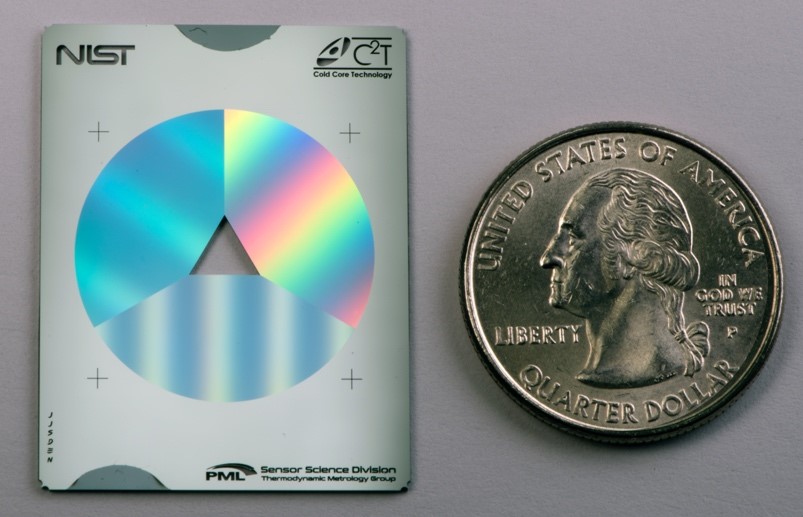

While the CAVS is a laboratory-size standard, NIST seeks to make it become a replacement for the ionization gauge by leveraging photonics to shrink it into a manageable package. This portable version of the CAVS, the p-CAVS, is currently under development. At its heart is a photonic grating chip that takes a single input beam and makes three more necessary for trapping atoms (Figure 2). In addition, the chip has an atomic aperture behind which the alkali source is placed. The aperture allows the input beam to pass and interact with the atoms from the source for longer, pre-slowing atoms that would otherwise never be trapped. This key innovation allows to trap Li atoms, an ideal sensor atom for vacuum measurements.

According to NIST the next generation of cold-atom based sensors promises a revolution in metrology, impacting the measurement of acceleration, rotation, magnetic fields, electric fields, blackbody radiation, temperature, vacuum and even time. NIST is focused on bringing this technology to practical use and building up a new measurement future with cold atoms.

Built-in flexibility

All-metal vacuum valves typically use stainless steel on both seal sides, poppet and seat. This "hard-on-hard" sealing inevitably leads to deformation, which limits the number of closing cycles - and requires frequent replacement. The VATRING technology used in VAT all-metal valves is based on a stainless steel ring that is inserted between the valve disc and the valve seat, and its shape provides dynamic sealing performance that normal "hard-on-hard" sealing systems do not offer. As a result, the technology enables a high number of closing cycles.

"Hard-on-hard" sealing valve solutions are increasingly relevant not only in the field of high-energy physics applications, but are also finding their way more and more into classic industrial applications, accompanied by growing demands on the quality of the vacuum in manufacturing processes," summarizes Martin Greuter, Sector Manager Coating, Scientific Instruments and Research at VAT. "Thanks to our comprehensive know-how in dynamic sealing technologies, VAT is the right partner for all requirements in this area."