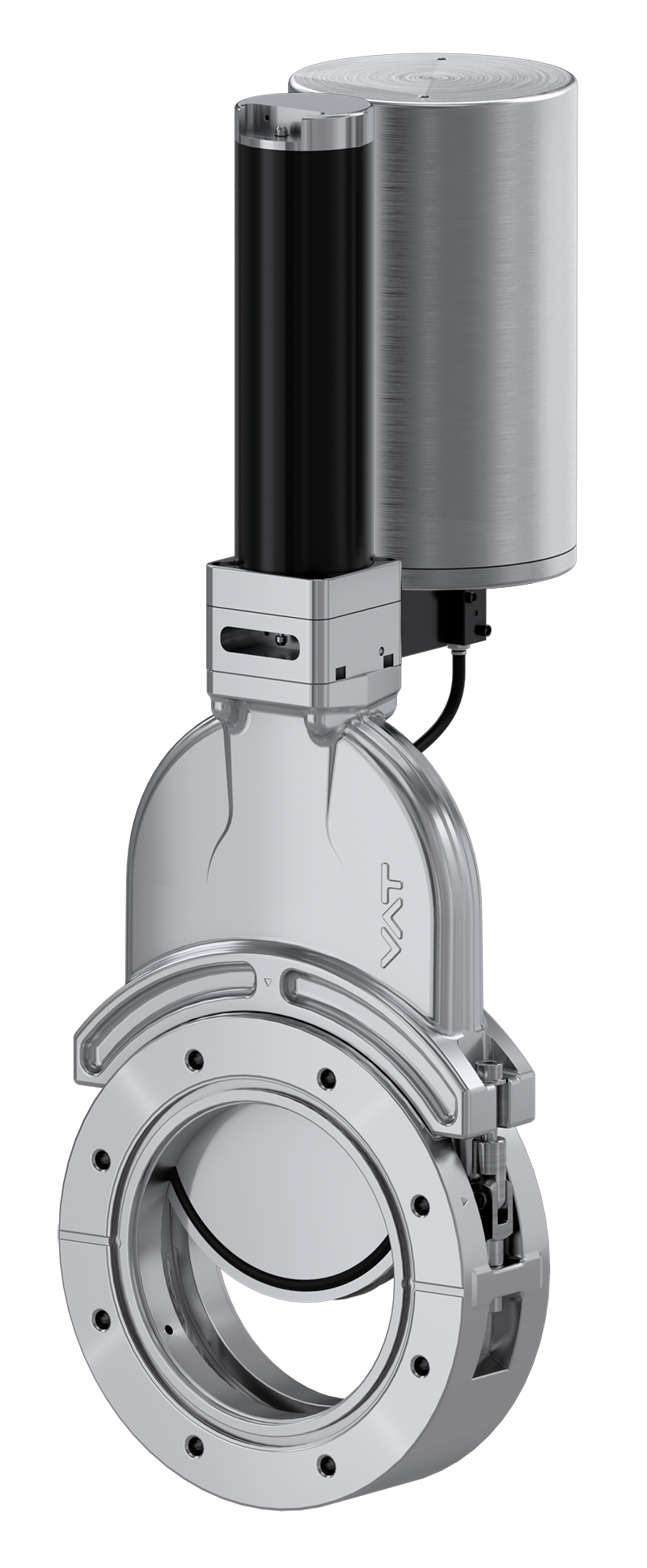

The reliable functioning of vacuum valves is crucial for the safety and quality of many production processes. A compressed air failure can lead to malfunctions in pneumatically driven vacuum valves. This can have serious consequences depending on the areas in which the valves are used. Safety compressed air accumulators on the valve are a good protection in such cases.

Production systems are pneumatically driven and controlled in many areas of application. This is particularly true for vacuum systems. Slight leaks in the compressed air system are usually compensated for by oversizing the central compressors. Backup compressors are used in the event of a compressor failure, and if larger leaks occur locally, check valves prevent the failure of the entire system.

However, these systems cannot prevent local leakages or brief pressure drops from causing valve malfunctions. For this reason, single-acting pneumatic actuators are traditionally used for vacuum valves, in which a spring presses the disc of the valve into either the open or closed position in the event of a compressed air failure. This solution is tried and tested and is part of the standard vacuum valve design. However, only one option is offered at a time and this would have to be changed by modifying the valve if necessary. Also, generally it is not an option for double-acting pneumatic actuators and pneumatic 3-position or control valves.

With double-acting pneumatic actuators and pneumatic 3-position or control valves, only a direct compressed air reservoir at the valve can help. In these systems, a small compressed air tank with sufficient pressure volume to change the valve position ensures the function of the valve in an emergency. The local compressed air supply allows the valve to function in such a way that it can be moved to the predefined emergency position. This emergency position can be easily changed without manual modifications to the valve.

The accumulators can be configured so that they are activated at a defined pressure drop value and then disconnect the valve from the compressed air system to compensate locally for the pressure drop.

The compact design of the accumulators means that they only expand the overall volume of the valves to a limited extent and can therefore be installed almost anywhere where standard valves without accumulators have been installed up to now. However, external installation of the compressed air accumulator is also possible. The accumulators do not require any additional installation or maintenance and are thus subject to the same maintenance cycle as the standard versions of the valve.

Compressed air safety accumulators are thus an important addition for vacuum valves in sensitive systems where high demands are placed on process safety.

Compressed air safety accumulators are available as a standard option for the 09.1, 10.8, 11.1 and 12.1 series. For other pneumatically actuated valves on request. For detailed information please refer to compressed air safety storage options for vacuum valves.

If you would like to learn more, please contact us.