FAQ Vacuum Transfer Valves

What are a vacuum transfer valves?

A vacuum transfer valve is a crucial component in vacuum systems, designed to control the transfer of substrates between different chambers while maintaining high vacuum conditions. These valves are essential in applications such as semiconductor manufacturing and research laboratories.

What considerations are important when choosing vacuum transfer valves?

When selecting a vacuum transfer valve, consider the following factors:

Application Requirements: Understand the specific needs of your process, including vacuum levels, material compatibility, and operational cycles.

Valve Body Material: Choose materials like aluminum, stainless steel or hard anodized options based on the operational environment and process requirements.

Flanges and Seals: Ensure the valve has appropriate flanges and seals for your system to maintain vacuum integrity.

Durability and Maintenance: Consider the valve’s durability and ease of maintenance to ensure long-term reliability and performance.

Customization Options: Look for valves with customizable features to meet unique application needs, such as special coatings or materials. Consider valves with customizable gate features, such as self-locking seals and easy disassembly for maintenance.

Actuator Type: Select the appropriate actuator for your application, whether manual, pneumatic, or electric, to ensure optimal control and precision.

Position Indicator: Ensure the valve includes a position indicator for precise monitoring and control of the valve’s status.

Application Requirements: Understand the specific needs of your process, including vacuum levels, material compatibility, and operational cycles.

Valve Body Material: Choose materials like aluminum, stainless steel or hard anodized options based on the operational environment and process requirements.

Flanges and Seals: Ensure the valve has appropriate flanges and seals for your system to maintain vacuum integrity.

Durability and Maintenance: Consider the valve’s durability and ease of maintenance to ensure long-term reliability and performance.

Customization Options: Look for valves with customizable features to meet unique application needs, such as special coatings or materials. Consider valves with customizable gate features, such as self-locking seals and easy disassembly for maintenance.

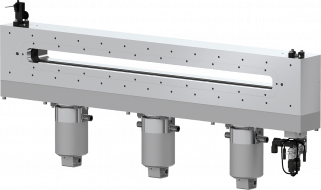

Actuator Type: Select the appropriate actuator for your application, whether manual, pneumatic, or electric, to ensure optimal control and precision.

Position Indicator: Ensure the valve includes a position indicator for precise monitoring and control of the valve’s status.

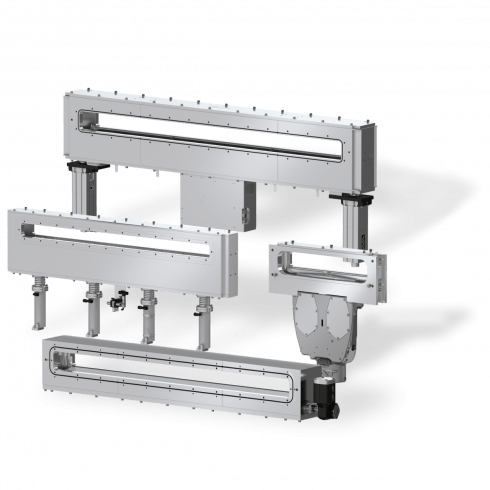

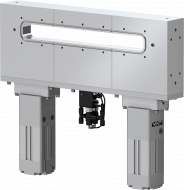

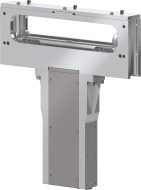

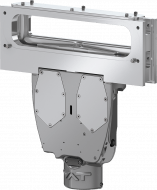

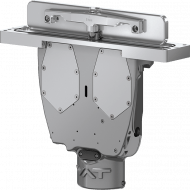

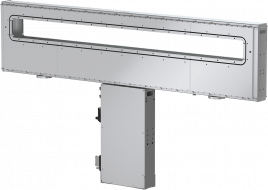

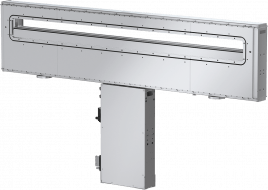

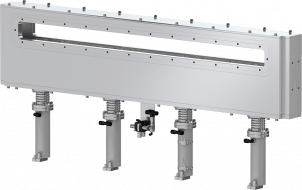

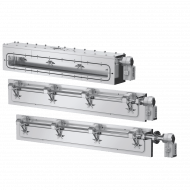

What distinguishes VAT vacuum transfer valves?

VAT vacuum transfer valves are renowned for their precision, reliability, and advanced engineering. Key features include:

High Performance: Designed to meet the stringent demands of advanced manufacturing processes, ensuring high vacuum conditions and minimal particle generation.

Customization: VAT offers tailored solutions, including various body materials and flanges, to fit specific application needs.

Durability: Built with high-quality materials such as hard anodized aluminum to ensure long-lasting performance even in the most demanding environments.

Comprehensive Service and Support: VAT provides extensive resources and support, including spare parts and maintenance services, to ensure optimal valve performance.

High Performance: Designed to meet the stringent demands of advanced manufacturing processes, ensuring high vacuum conditions and minimal particle generation.

Customization: VAT offers tailored solutions, including various body materials and flanges, to fit specific application needs.

Durability: Built with high-quality materials such as hard anodized aluminum to ensure long-lasting performance even in the most demanding environments.

Comprehensive Service and Support: VAT provides extensive resources and support, including spare parts and maintenance services, to ensure optimal valve performance.