Semiconductor Production

With constantly evolving processes and the increasing complexity of cutting-edge fabs, semiconductor manufacturing is a relentless cycle of innovation. Because the presence of particles no bigger than a molecule can ruin a semiconductor chip – and reduce yields – vacuum valves must provide uncompromising performance in terms of particle avoidance (to avoid wafer damage) and reliability.

Learn more

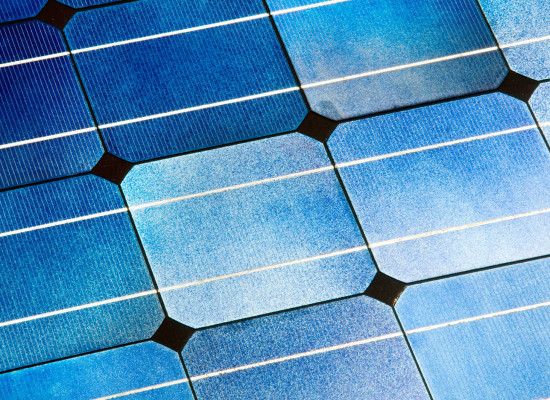

Solar Panel Production

Manufacturers of solar modules face many production challenges: growing substrate dimensions, increasing throughput while maintaining high plant availability and process stability, reducing operating costs. Conditions that the vacuum valves used, especially transfer valves, must also face with innovative concepts.

Learn more

Display Production

The global display industry is driven by ever larger glass substrate dimensions, the shift from LCD to OLED technology, more complex display manufacturing processes, and the optimization of existing production facilities. These dynamics demand high-performance vacuum valve solutions that contribute to quality and productivity improvements.

- Display Dry Etching

- Sputtering

- Thin-film Encapsulation (CVD)

- OLED Evaporation

- Ion Implanting

- CVD

- OLED Inkjet Printing

- Sub-fab Systems

Lighting Production (LED, OLED)

As LED and increasingly OLED lighting has developed into a mass market, production is strongly cost-driven. High production quality and high volumes therefore also define the framework for the development of the required vacuum valve solutions. The decisive factors here are reliability, low maintenance and low operating costs.

Learn more

Sub-Fab Systems

Sub-fab processes can be challenging: corrosive, abrasive, and toxic gases and/or condensation and high levels of by-products in the gas stream can all severely affect the functionality and reliability of vacuum valves. Key functions of vacuum valves include: Prevention of backflow contamination, flow rate control and pump isolation.

Learn more

Research

The spectrum of vacuum-assisted R&D applications ranges from specialized large-scale research facilities up to laboratory applications. These applications all explore the limits of what is technically possible – to improve measurement sensitivity and quality. Vacuum valves used in R&D applications feature improved controllability, reliable, long-term stable isolation even under extreme conditions, and inert physical characteristics while avoiding any emissions.

Learn more

Scientific Instruments

The spectrum of scientific instruments ranges from customized large-scale facilities in governmental or semi-governmental research institutions to standardized high-tech instruments such as mass spectrometers and electron microscopes used in various fields.

Learn more

Thin Film Coating

A number of different processes are used for thin film coating processes, e.g. CVD, PVD, MOCVD or PECVD. All processes have in common that they take place under controlled atmospheric conditions, e.g. under argon atmosphere and under vacuum. Precise control of the vacuum and gas distribution is crucial for the efficiency of the coating process. VAT valve technologies set standards in this area.

Learn more

Industry

The number of vacuum applications is almost unlimited. In almost all industrial sectors, vacuum applications play an important role in solving a wide variety of production and manufacturing tasks. VAT has the right solution for almost all applications.

Learn more

Medical & Pharmaceutical Applications

Vacuum, and thus vacuum valve solutions, are critical for various medical fields and devices. The spectrum ranges from standard requirements for reliable isolation and control to requirements for high temperature resistance, freedom from particle emissions and freedom from maintenance. VAT offers solutions for all issues.

Learn more